Search

Products

News

Based on your search criteria, we have found the following related

""products:

Based on your search criteria, we have found the following related

""news:

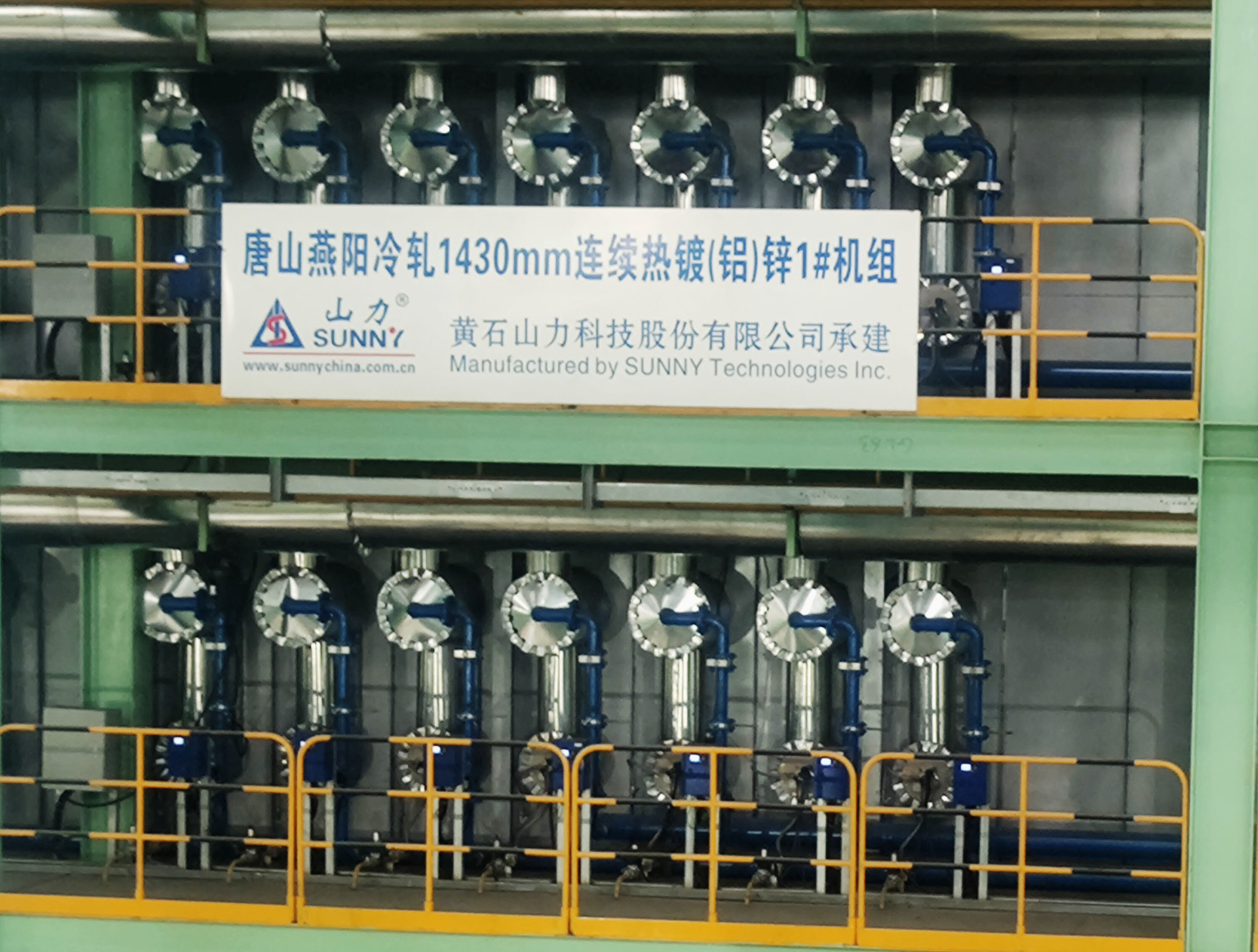

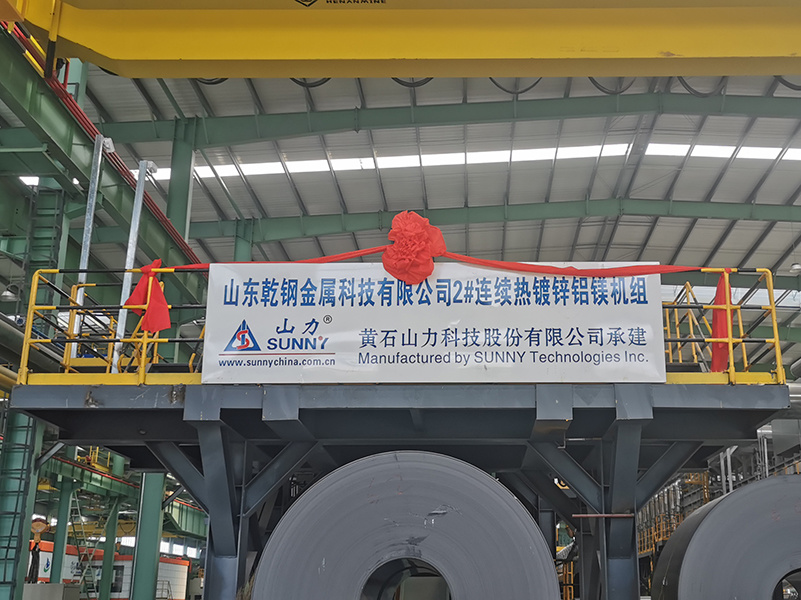

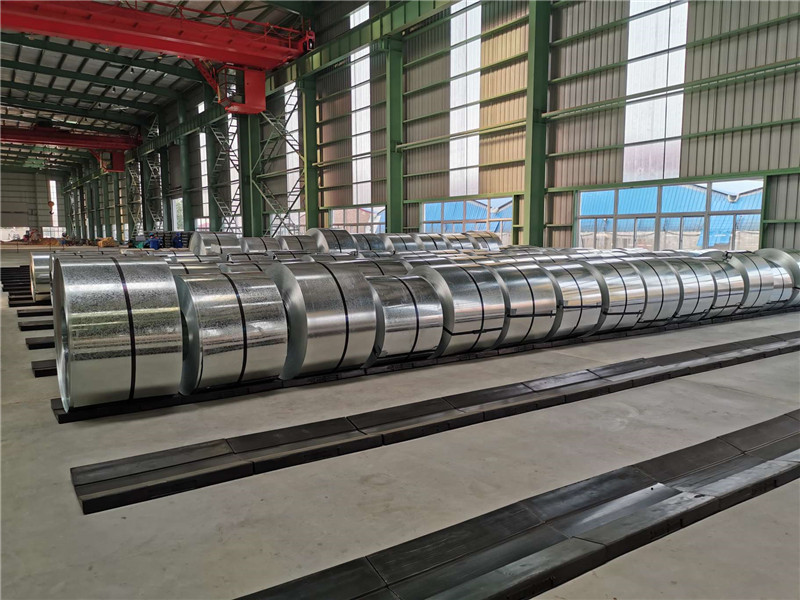

A set of descriptions about zinc pots

Oct 23,2020

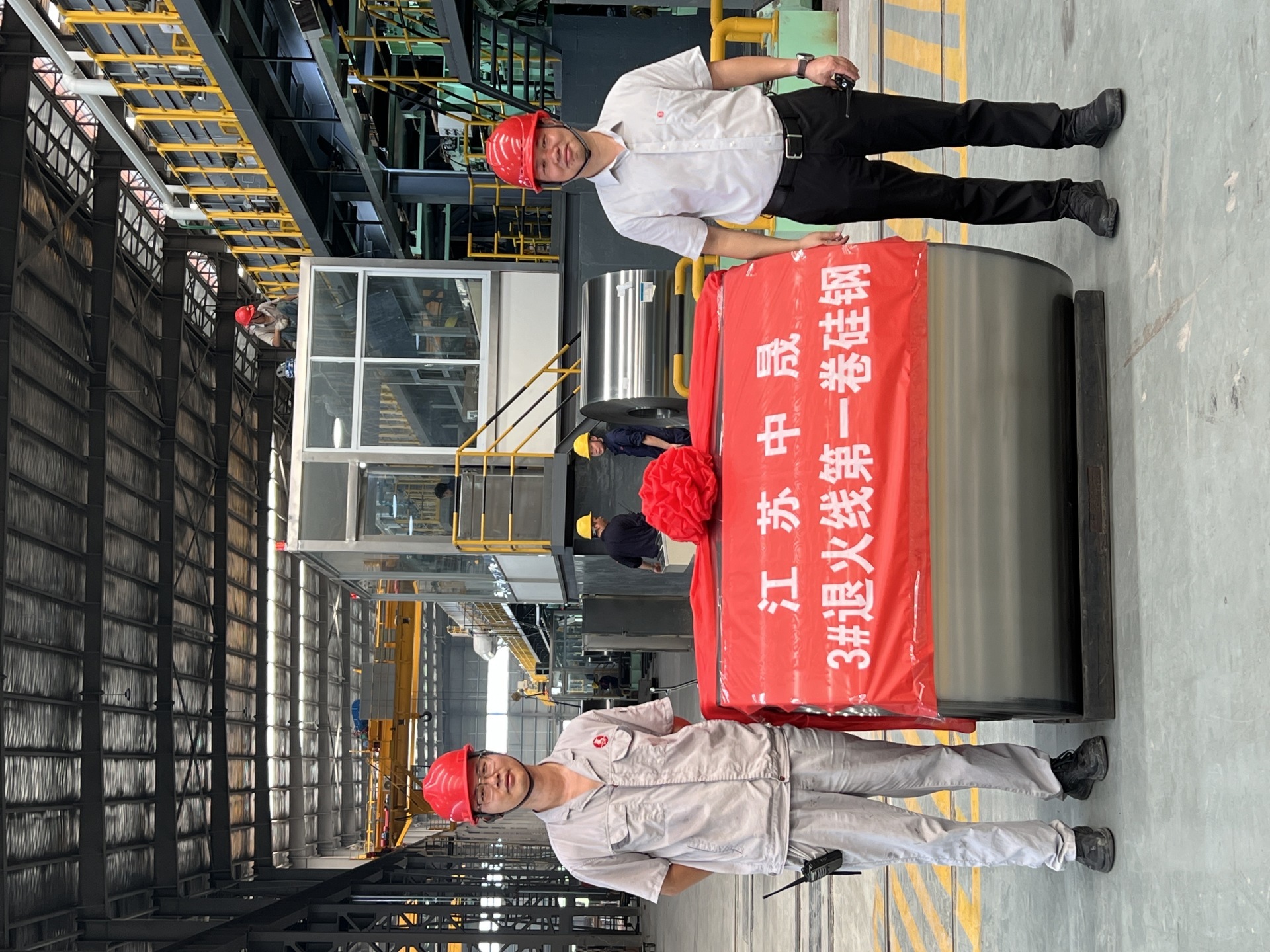

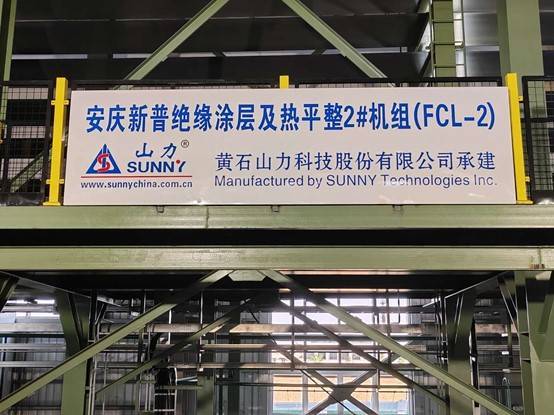

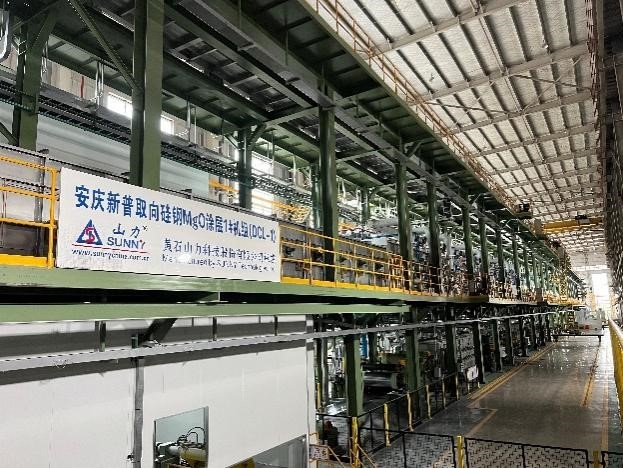

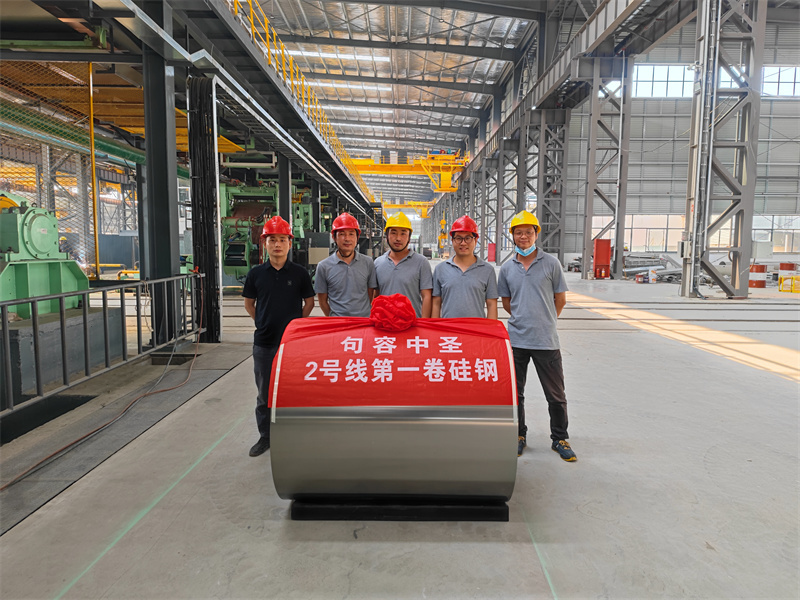

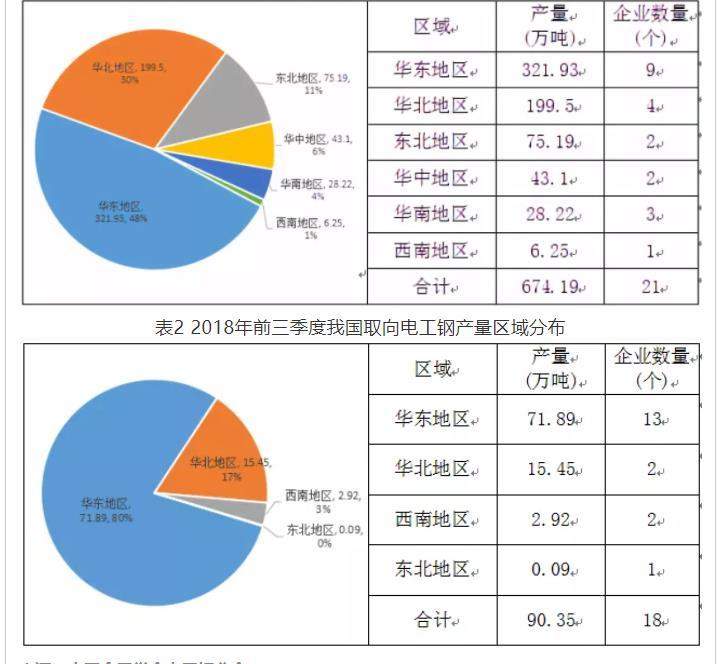

Inhibitors in grain-oriented silicon steel

Oct 12,2020

Warm farewell to retiring employees

Dec 03,2019

Brave to "ping" Bo, "pong" moved my heart

Nov 22,2019

What are the alloy strengthening mechanisms?

Oct 09,2018

Four common combustion technologies in industry

Oct 08,2018

Wechat

Wechat