Solutions

Continuous decarburization and annealing unit for cold-rolled silicon steel (CNGO)

Category: Solution

The cold-rolled non-oriented silicon steel (CNGO) is degreased, decarburized and annealed, and recrystallized annealed under a protective atmosphere to reduce the carbon content of the strip to the specified range, to grow the grains, improve the magnetic properties, eliminate stress, and apply an insulating layer.

Details

For cold-rolled non-oriented silicon steel (CNGO) Surface degreasing is performed, and decarburization annealing and recrystallization annealing are performed in a protective atmosphere. The carbon content of the strip is reduced to the specified range, the grain size is increased, the magnetic level is improved, stress is eliminated, and an insulating layer is applied.

Main Technical Parameters

Raw materials: Cold-rolled hard-state steel coils of non-oriented electrical steel (Si≤2.0%) W470-W1300

Strip carbon content: C≤50ppm

Strip thickness: 0.35-0.65mm

Strip width: 900-1250mm

Product: Cold-rolled electrical steel coil

Representative specifications: 50W470-50W600 50W800-50W1300

Quality standard: GB/T2521-1996

Carbon content: C≤27ppm

Unit speed: Inlet 0-200mpm, process section 0-135mpm, outlet section 0-200mpm

Annual output: 200,000tpy

Energy saving method: Comprehensive utilization of waste gas heat recovery, SUNNY patent

Continuous decarburization annealing furnace: Non-oxidizing heating (NOF) + full radiation tube heating (RTF), vertical and horizontal

Fuel type: Natural gas, liquefied petroleum gas

Decarburization method: Continuous decarburization with protective gas

Insulating layer coating: Using roller coater + coating drying and curing

Welding equipment: Narrow lap seam welder

Degreasing method: Chemical degreasing + electrolytic degreasing + three-stage water rinsing, vertical or horizontal

Electrical control system: SIEMENS or ABB AC frequency conversion automatic control system

Industrial automation: SIEMENS or ABB intelligent automatic control system

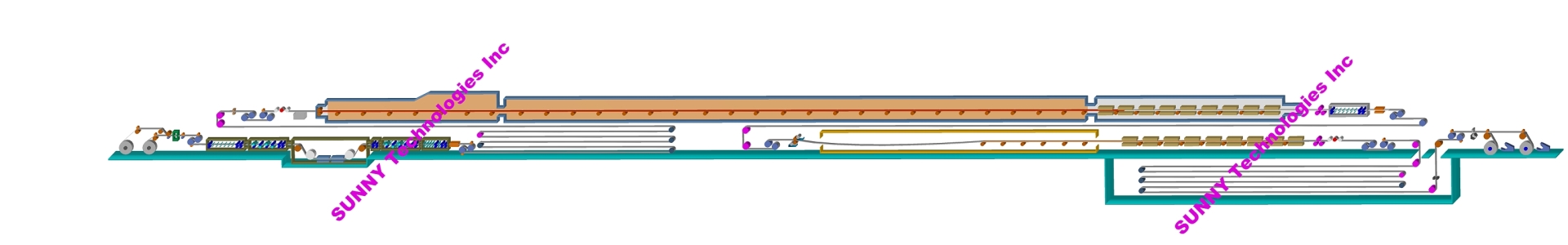

Main production process flow

Uncoiling → Welding → Degreasing (alkaline spraying → alkaline scrubbing → electrolytic degreasing → hot water cleaning → drying) → Decarburization annealing → Cooling → Coating insulation layer → Sintering → Cooling → Surface inspection → Slitting → Coiling

Wechat

Wechat