blog INFORMATION

blog

To become a globally recognized equipment supplier through advanced sheet metal processing technologies and premium services.

Customer Focus, Scientific Management, Dynamic Innovation, and Value Realization

300

+

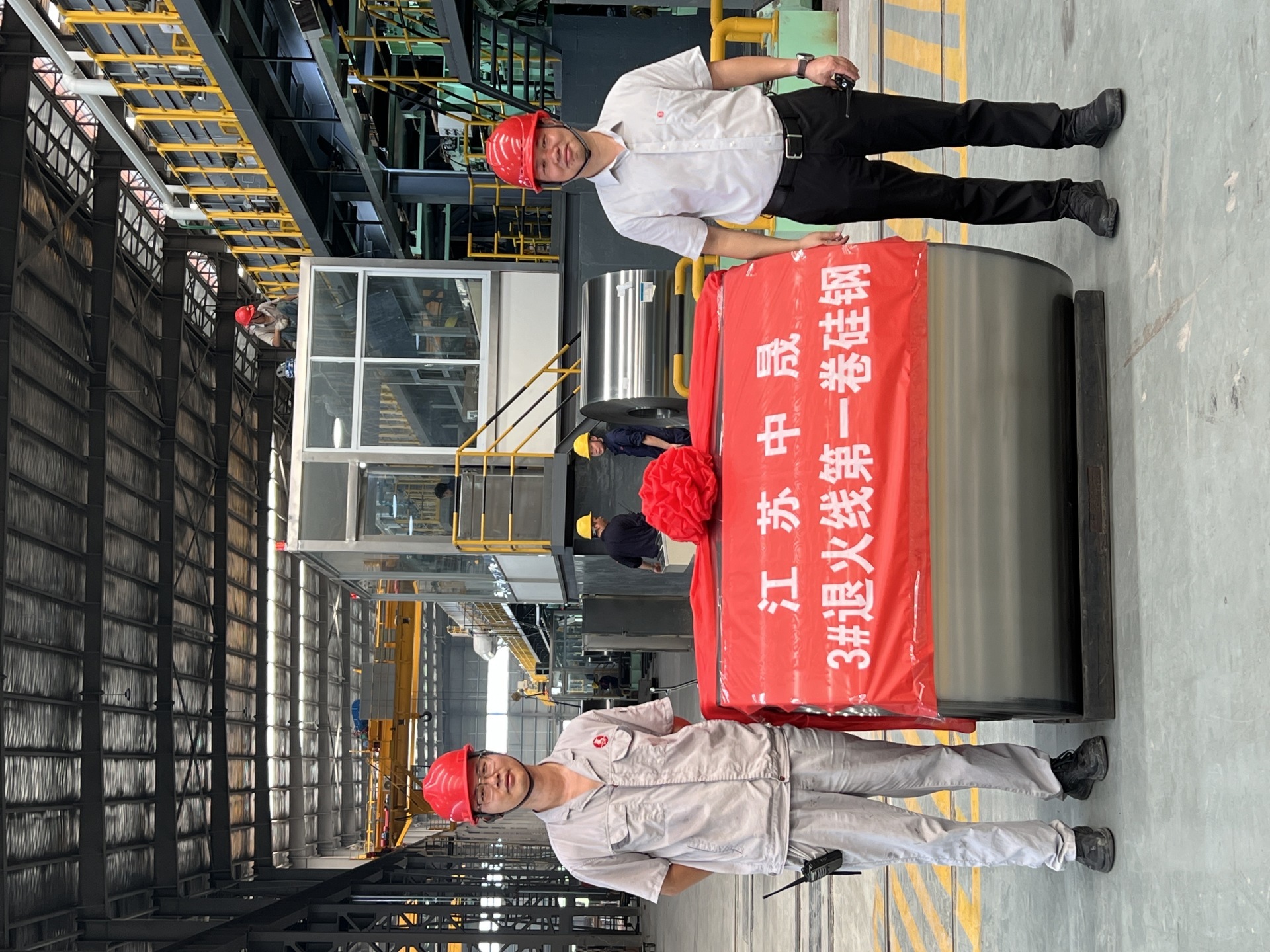

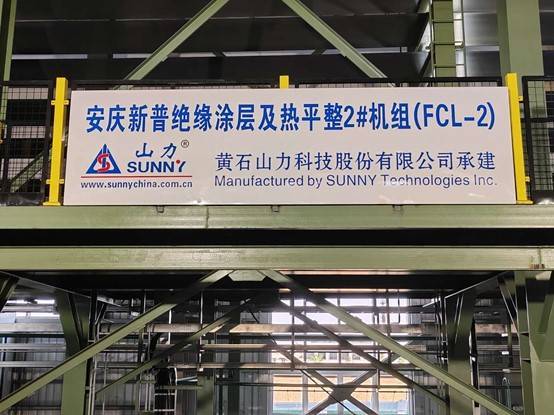

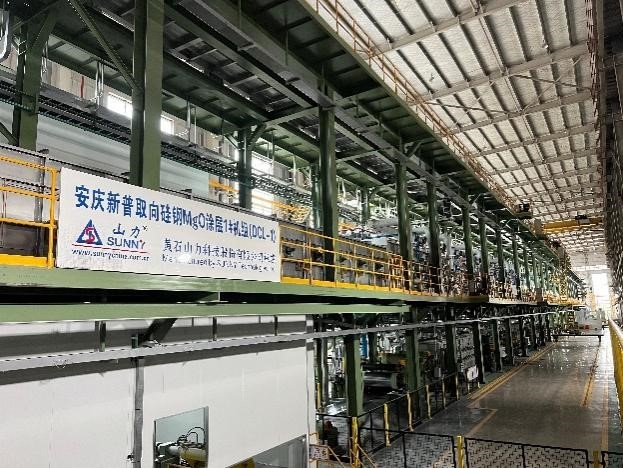

Complete engineering projects at home and abroad

70

+

Patented technology

35

+

Market Share

7

+

Major scientific and technological achievements

SOLUTION

case

SUNNY company was recognized as a"national high-tech enterprise",and SUNNY trademark was awarded"China well-known trademark".

SUNNY Technologies Incorporation Limited

With sheet metal processing technologies at our core, we provide advanced, comprehensive sheet system solutions to domestic and international customers

National Service Hotline

Wechat

Wechat