News Center

China's first second four-layer horizontal oriented silicon steel production line has been successfully put into operation

Category: SUNNY News Publish Time:2023-09-27

China's first second four-layer horizontal oriented silicon steel production line successfully put into operation

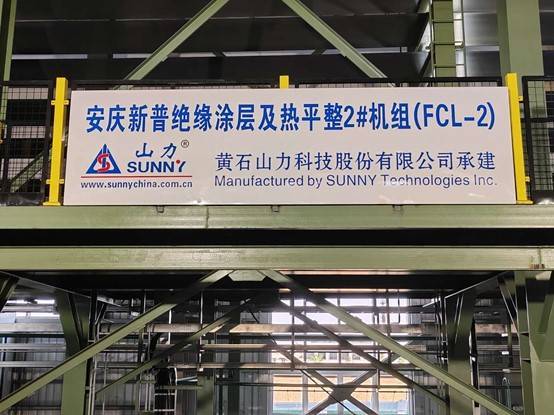

On September 17, 2023, the first finished coil of the Anqing Xinpu Electric Equipment Co., Ltd. (hereinafter referred to as Anqing Xinpu) oriented silicon steel coating insulation layer and hot leveling No. 2 unit general contracting construction (FCL-2), which was general contracted by Huangshi Shanli Technology Co., Ltd. (hereinafter referred to as Shanli Technology), was successfully put into operation. This marks the successful commissioning of China's first second four-layer horizontal oriented silicon steel production line under a one-time thermal load.

Anqing Xinpu's parent company is Wuxi Putian Iron Core Co., Ltd., a private high-tech enterprise focusing on the manufacturing, research and development, and sales of power transformer iron cores. It is the main drafting unit of the national standard GB/T32288 "Electrical steel core for power transformers". Its Putian Iron Core brand sales and service network covers many provinces, autonomous regions, and municipalities in China, and extends to more than 30 countries and regions in South America, Europe, the Middle East, and Southeast Asia. Its products have been widely used in national power grids, nuclear power plants, high-speed railways, subways, solar energy, offshore wind power, large residential areas, etc. Its output and scale have maintained industry leadership for many years, providing one-stop high-quality services and innovative solutions for more than 200 transformer manufacturers worldwide. The establishment of Anqing Xinpu Electric Equipment Co., Ltd. mainly provides high-quality CGO products for its parent company.

In 2022, Wuxi Putian's products extended upwards, and Anqing Xinpu Electric Equipment Co., Ltd. was established in Anqing. Through independent innovation, it signed a contract with Shanli Technology to build the first four-layer horizontal oriented silicon steel insulation coating and hot leveling unit, which was completed and put into operation in April 2023. In the same year, the second unit (FCL-2), with the active cooperation of Anqing Anpu, Shanli Technology summarized the experience of the first unit, carefully designed in terms of process layout, transmission control, and instrument configuration, and completed all drawings and equipment development work in February 2023. Construction began in March of the same year, strictly implementing the Putian Iron Core 6S management standards. Through joint cooperation between the two parties, the unit system debugging conditions were met in just 5 months, and successful commissioning was achieved in 6 months, achieving the engineering speed of "Shanli Technology" and "Anqing Xinpu" joint construction.

The main function of this unit is to remove the residual MgO on the surface of CGO caused by the previous process, and then perform light pickling, coating insulation layer and drying, sintering, and hot leveling. The designed annual processing capacity is 85,000 tons/year, and the processed strip steel specifications are 0.15-0.23mm x 800-1350mm, with a designed unit process speed of max. 120m/min.

So far, the Anqing Xinpu FCL-2 unit constructed by Shanli Technology, as well as the oriented silicon steel (CGO) annealing coating No. 1 unit (DCL-1 unit) and the oriented silicon steel (CGO) hot leveling coating No. 1 unit (FCL-1 unit) in the Phase I project, have all been successfully put into operation. The product quality and stable operation of the production line have been unanimously praised by customers and the industry. Shanli Technology will continue to provide the highest quality and comprehensive services to domestic and foreign customers with "Shanli speed" and "Shanli standards", and with cutting-edge technology and high-end quality.

Keywords: China's first second four-layer horizontal oriented silicon steel production line has been successfully put into operation

Related News

Shanli Technology's Bao Huang electroplating production line successfully put into operation

2023-04-23

Warm farewell to retiring employees

2019-12-03

Brave to "ping" Bo, "pong" moved my heart

2019-11-22

Professor Li Jiuling's Report on the Development of Zinc, Aluminum, and Magnesium Plated Sheets

2019-05-20

Shanli Co., Ltd. passed the new version of the quality management system certification audit

2017-07-24

Wechat

Wechat