News Center

Shanli Technology's Bao Huang electroplating production line successfully put into operation

Category: SUNNY News Publish Time:2023-04-23

Based on advanced technology, creating high-quality projects

Shanli Technology's construction of Baogang Huangshi's electrogalvanized plate production line successfully put into production

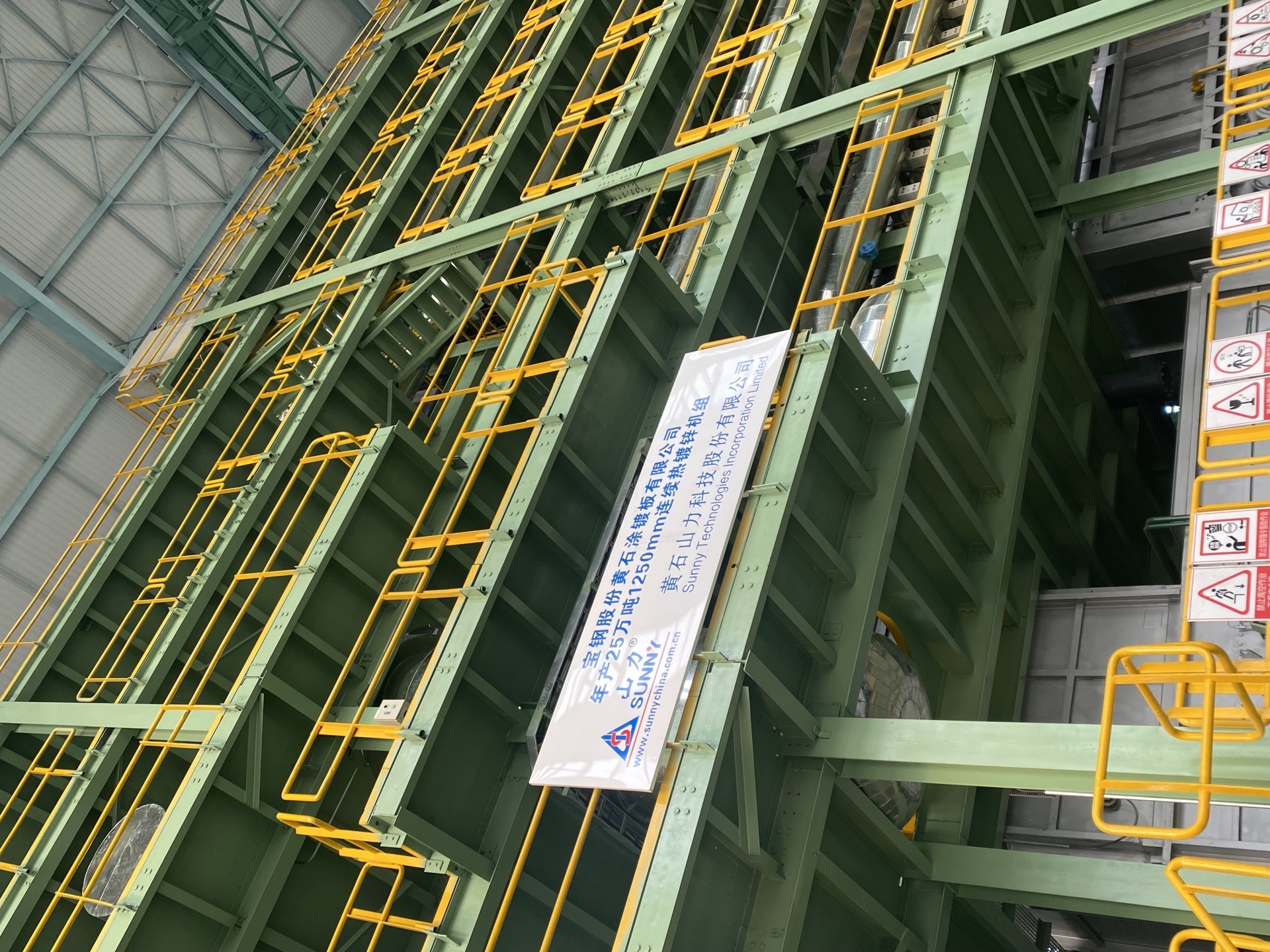

On February 28, 2023, the second phase project of the electrogalvanized plate production line of Baogang Group Huangshi Electrogalvanized Plate Co., Ltd. (hereinafter referred to as "Baohuang"), constructed by Huangshi Shanli Technology Co., Ltd. (hereinafter referred to as "Shanli Technology"), successfully rolled out its first coil of home appliance galvanized steel sheet. This marks the complete success of Baohuang's Phase II continuous annealing and galvanizing project. This not only symbolizes the successful implementation of Baohuang's large-scale relocation and upgrading project from the city to the industrial park, but also witnesses the successful cooperation between Shanli Technology and a Fortune 500 company!

The "403 hot-dip galvanizing unit" put into production this time was relocated and renovated from the "401 continuous annealing unit" of the old Baohuang factory. It is the final process in the entire Phase II project's strip processing flow that produces products for customers. Raw materials are provided by the upstream pickling process (also constructed and operated by Shanli Technology) and cold rolling process. In this process, the steel is cleaned, degreased, annealed and reduced, galvanized, smoothed, straightened, and passivated (fingerprint-resistant), ultimately resulting in high-performance, aesthetically pleasing home appliance galvanized steel sheet products. Due to the age of the original "401 continuous annealing unit" and the lack of detailed drawings, this construction project not only required a thorough understanding of the original unit's process technology and equipment model and size, maximizing the reuse of the existing steel structure and some equipment; it also required combining the characteristics of the original unit and integrating Shanli Technology's existing advanced technologies to meet Baohuang's advanced process technology and stringent product standards. To complete this challenging task, based on the company's leading vertical continuous hot-dip galvanizing technology, the Shanli Technology team repeatedly communicated and discussed with Baohuang's technical personnel, conducting on-site measurements and demonstrations. From design drawings, new technology development, equipment manufacturing, on-site construction, to process debugging, Shanli Technology pursued excellence in every aspect. Through the collision of Shanli Technology's advanced strip deep processing design and construction technology with Baohuang's valuable production technology experience and world-class vision, this challenging project was successfully completed.

The "403 hot-dip galvanizing unit" inherits the historical mission of the original 401 galvanizing unit in Tuanchengshan factory area. Its commissioning is significant, taking place against the backdrop of Baohuang's deep implementation of China Baowu's "Three Refinements and Four Modernizations" and "Higher Standards, Better than Urban Areas, Integration into the City" business philosophy, actively responding to Huangshi City's "withdrawal from the city to the park" green development requirements, and the phased advancement of the overall relocation of the Tuanchengshan factory area to the Huangshi New Port (Logistics) Industrial Park.

We wish Shanli Technology and Baohuang more cooperation in the future, and together make due contributions to the development of China's continuous heat treatment industry for strip steel!

Keywords: Shanli Technology's Bao Huang electroplating production line successfully put into operation

Related News

Shanli Technology's Bao Huang electroplating production line successfully put into operation

2023-04-23

Warm farewell to retiring employees

2019-12-03

Brave to "ping" Bo, "pong" moved my heart

2019-11-22

Professor Li Jiuling's Report on the Development of Zinc, Aluminum, and Magnesium Plated Sheets

2019-05-20

Shanli Co., Ltd. passed the new version of the quality management system certification audit

2017-07-24

Wechat

Wechat