News Center

Shanli Shares Creates High-Quality Engineering Projects—Successfully Puts into Production the No. 2 Silicon Steel Continuous Annealing and Tempering Unit for Jurong Zhongsheng

Category: SUNNY News Publish Time:2022-05-26

Shanli Shares Creates High-Quality Engineering Projects

Construction of Jurong Zhongsheng No. 2 Silicon Steel Continuous Annealing Unit Successfully Put into Production

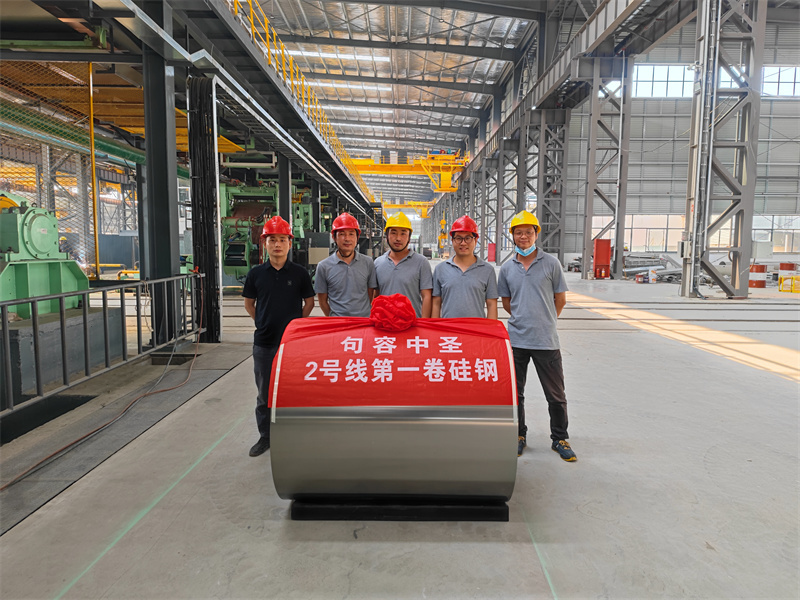

On May 25, 2022, Jurong Zhongsheng Band and Strip Technology Co., Ltd. in Zhenjiang City, Jiangsu Province, reported good news: the Jurong Zhongsheng No. 2 silicon steel continuous annealing unit project, undertaken by Huangshi Shanli Technology Co., Ltd. (hereinafter referred to as: Shanli Shares), was successfully put into production! The product has good surface quality, and its magnetic properties and surface coating meet national standards. In particular, the unit equipment operates stably without any failures, which has been fully affirmed by the owner. At the same time, it has laid a new foundation for the long-term friendly cooperation between Shanli Shares and Jurong Zhongsheng.

This project is a silicon steel annealing unit. The function of this unit is to degrease the cold-rolled unoriented medium and low grade silicon steel strip, and then perform recrystallization annealing under a protective atmosphere to enlarge the grains, improve the magnetic level, eliminate stress, and apply an insulating layer. The designed annual production capacity is 250,000 tons. Shanli Shares gives full play to its overall design experience of nearly 100 continuous units at home and abroad, adopts advanced and reliable annealing production processes at home and abroad, especially its experience in silicon steel, and combines it with the overall requirements of the workshop layout to make the logistics, auxiliary media supply and discharge, and production operations of this unit reasonable, practical, and convenient. In particular, the invention patent for the comprehensive utilization of waste heat from continuous annealing units obtained by Shanli Shares is used in this unit, which greatly reduces the energy consumption of the unit and realizes the organic combination of the owner's production efficiency and the concept of energy saving and emission reduction.

This project is the third cooperation between Jurong Zhongsheng and Shanli Shares in two years, following the commissioning of the No. 1 silicon steel continuous annealing line in September 2021 and the 480,000-ton pickling unit in January 2022. While the first two units continue to stably produce high-quality products, the successful commissioning of this project will provide sufficient firepower support for its deep cultivation of the silicon steel market.

During the critical period of the project construction, the epidemic raged, and Zhenjiang, located on the edge of the eye of the storm, was severely impacted by the epidemic. Materials, equipment, and personnel could not enter normally. The project progress was severely restricted, and the owner was very anxious. If the project commissioning was seriously delayed, it would hinder its market layout. Shanli Shares responded to the customer's urgent needs, gave full play to its excellent organizational coordination and resource integration capabilities, and the flexible emergency handling capabilities accumulated from hundreds of large and small projects. According to the urgency, the construction procedures were scientifically and reasonably adjusted, and the changes in epidemic prevention policies were closely monitored to arrange various resources. With concerted efforts, the project was finally completed and put into production as scheduled.

The haze of the epidemic is gradually dissipating, and the sunshine of the market is shining on the earth. Shanli people are fully prepared and have thrown themselves into the construction of a series of subsequent projects with full enthusiasm, making new contributions to the healthy and sustainable development of China's electrical steel industry.

Keywords: Shanli Shares Creates High-Quality Engineering Projects—Successfully Puts into Production the No. 2 Silicon Steel Continuous Annealing and Tempering Unit for Jurong Zhongsheng

Related News

Shanli Technology's Bao Huang electroplating production line successfully put into operation

2023-04-23

Warm farewell to retiring employees

2019-12-03

Brave to "ping" Bo, "pong" moved my heart

2019-11-22

Professor Li Jiuling's Report on the Development of Zinc, Aluminum, and Magnesium Plated Sheets

2019-05-20

Shanli Co., Ltd. passed the new version of the quality management system certification audit

2017-07-24

Wechat

Wechat