News Center

Putian Tiexin - Anqing Xinpu Electric Co., Ltd.'s Phase I Grain-Oriented Silicon Steel Project Successfully Put into Production!

Category: SUNNY News Publish Time:2023-07-21

Putian Iron Core - Anqing Xinpu Electric Co., Ltd.

Phase 1 Grain-Oriented Silicon Steel Project Successfully Put into Production!

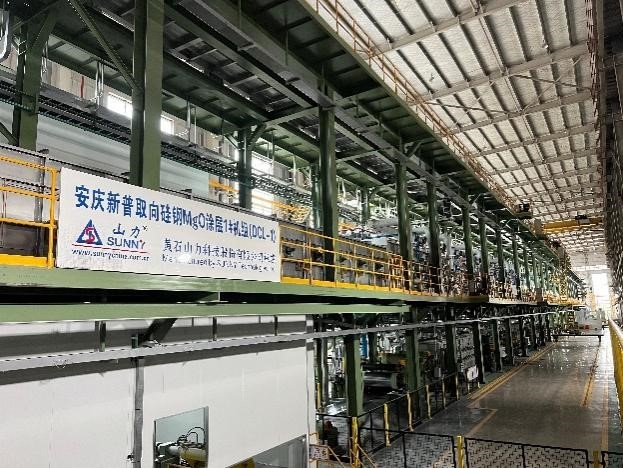

In the first quarter of 2023, the Anqing Xinpu Electric Co., Ltd.'s Phase 1 Grain-Oriented Silicon Steel (CGO) annealing and coating unit 1 (DCL-1) and grain-oriented silicon steel (CGO) hot leveling and coating unit 1 (FCL-1), which were constructed by Huangshi Shanli Technology Co., Ltd., successfully completed their initial hot load test runs; and achieved the overall project production target at the beginning of the second quarter.

Anqing Xinpu Electric Equipment Co., Ltd. is a subsidiary of Wuxi Putian Iron Core Co., Ltd. (hereinafter referred to as Putian Iron Core). Putian Iron Core is a privately-owned high-tech enterprise focusing on the manufacturing, research and development, and sales of power transformer cores. It is a major drafting unit of the national standard GB/T32288 "Electrical Steel Cores for Power Transformers", and also the affiliated unit of the Iron Core Application Branch of the China Electrical Appliances Industry Association. Its product sales and service network covers many provinces, municipalities, and autonomous regions across China, and extends to more than 30 countries and regions in South America, Europe, the Middle East, and Southeast Asia. Its products are widely used in national power grids, nuclear power plants, high-speed railways, subways, solar energy, offshore wind power, large residential areas, etc. For many years, its production and sales volume and scale have maintained a leading position in the industry, providing one-stop high-quality services and innovative solutions for more than 200 transformer manufacturers worldwide. The establishment of Anqing Xinpu Electric Equipment Co., Ltd. mainly provides high-quality CGO products for its parent company.

Based on Xinpu Electric's technological innovation, equipment, processes, and actual site conditions, Shanli Technology has "tailor-made" a grain-oriented silicon steel (CGO) annealing and coating unit and a grain-oriented silicon steel (CGO) hot tension leveling and coating unit. Among them, the grain-oriented silicon steel (CGO) annealing and coating unit performs surface degreasing, annealing, and MgO coating on the CGO steel coils after secondary cold rolling, with a designed annual processing capacity of 80,000 tons/year. The grain-oriented silicon steel (CGO) hot tension leveling and coating unit removes residual MgO on the CGO surface from previous processes, then performs light acid washing, insulation coating and drying, sintering, and hot leveling, with a designed annual processing capacity of 85,000 tons/year. The core equipment and technology of the two units are independently researched and developed by Shanli Technology, and their overall performance has reached the international advanced level.

During project implementation, both parties worked together, racing against time, and coordinating scientifically to effectively shorten the project duration. Currently, the Phase 2 silicon steel project, which is a joint effort between the two parties, is under intense construction. Shanli Technology will continue to provide Xinpu Electric with the best and most comprehensive services using cutting-edge technology and high-end quality.

Keywords: Putian Tiexin - Anqing Xinpu Electric Co., Ltd.'s Phase I Grain-Oriented Silicon Steel Project Successfully Put into Production!

Related News

Shanli Technology's Bao Huang electroplating production line successfully put into operation

2023-04-23

Warm farewell to retiring employees

2019-12-03

Brave to "ping" Bo, "pong" moved my heart

2019-11-22

Professor Li Jiuling's Report on the Development of Zinc, Aluminum, and Magnesium Plated Sheets

2019-05-20

Shanli Co., Ltd. passed the new version of the quality management system certification audit

2017-07-24

Wechat

Wechat