Solutions

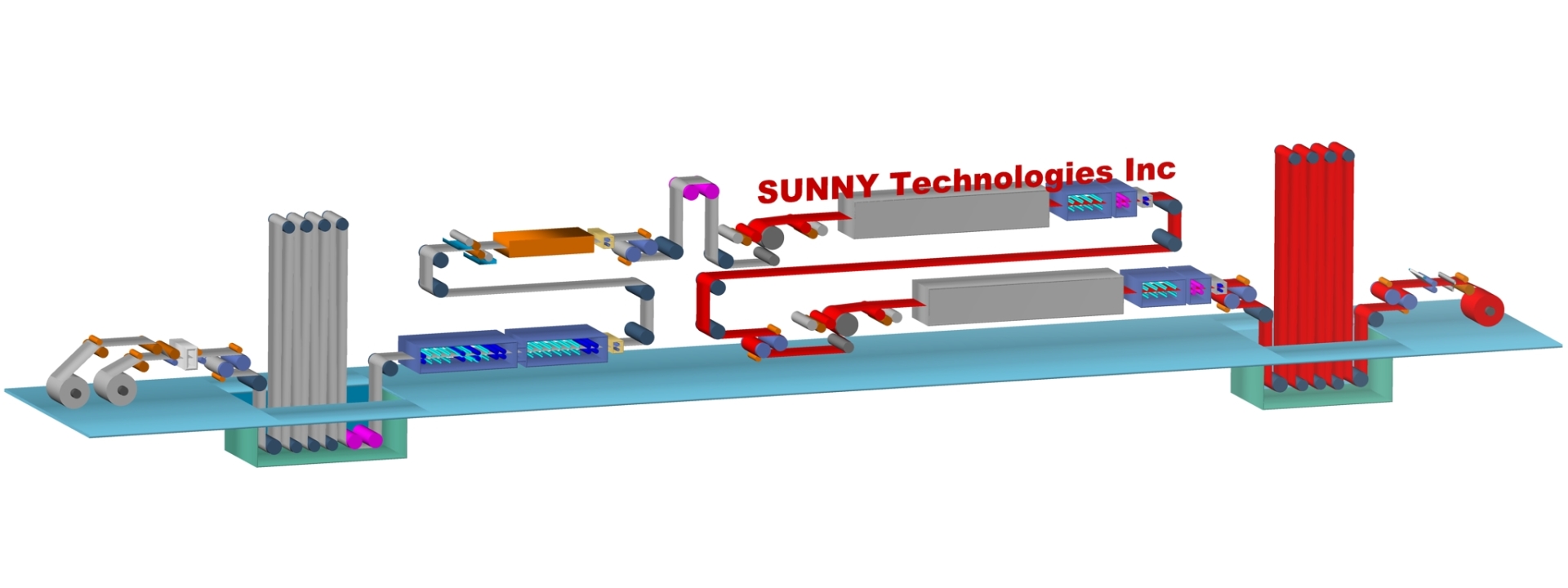

Continuous color-coated steel production line (PPGI, PPGL)

Category: Solution

A continuous roll coating line for steel strip applies a paint film coating to galvanized (aluminum) or aluminum substrates to further improve corrosion resistance and aesthetics, expanding the range of product applications.

Details

The continuous color-coating production line for steel strips applies a paint film coating to the base substrate of galvanized (aluminum) zinc or aluminum plates to further improve corrosion resistance and aesthetics, expanding the range of product applications.

Main Technical Parameters of the Production Line:

Raw materials: Galvanized steel coils (GI/GL), 800-1250mm × 0.2-1.2mm

Production line speed: 60-120 mpm

Color coating process: Two coats and two baking processes (for building materials), three coats and three baking processes (for home appliances)

The coating machine is designed with a glue roller, a metering roller, and a coating roller to precisely adjust the paint film thickness.

The system includes a curing oven and a waste gas incineration and waste heat recovery system. Fresh air (for high-quality products) or flue gas (for lower cost) is used to dry and cure the paint film, while simultaneously burning off volatile solvents in the paint, achieving both environmental protection and energy saving.

Uses a SIEMENS AC frequency control system

Uses a SIEMENS automated temperature control system

The main process is as follows:

Uncoiling, splicing, cleaning, chemical treatment, primer coating, curing, top coating, curing, inspection, slitting, and recoiling

Wechat

Wechat