Solutions

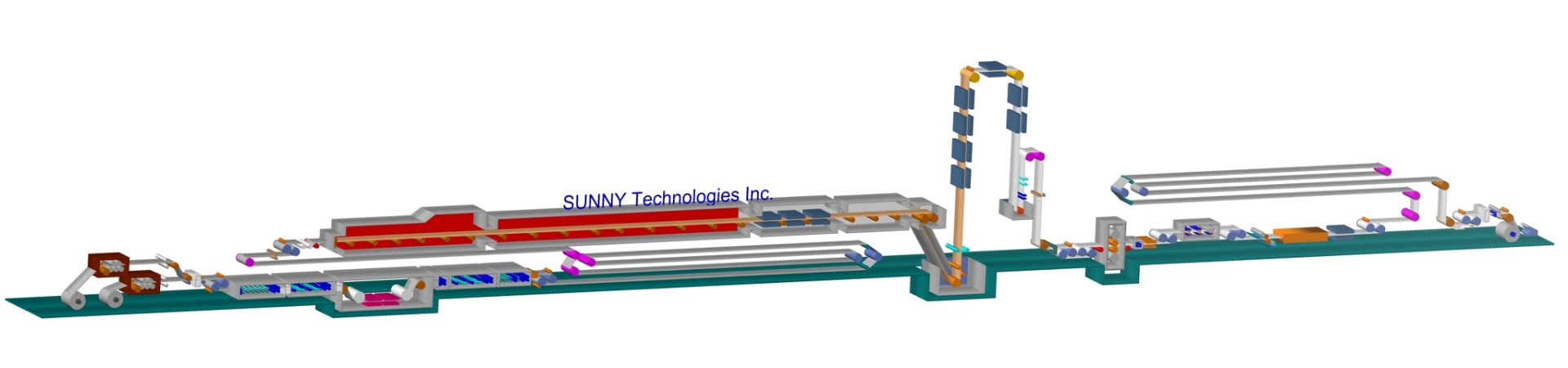

Continuous hot-dip galvanized steel sheet production line (HGI)

Category: Solution

Using hot-rolled steel as a raw material, a layer of zinc or zinc-aluminum alloy is applied to the surface of the strip steel through hot-dip galvanizing, which has strong cathodic protection performance, making it widely used in various fields such as industry, agriculture and construction, and becoming a widely used coated product today.

Details

Main Features of the Unit:

Raw materials: Steel strip width: 600-1550mm, thickness: 1.5-4.0mm, pickled hot-rolled low-carbon steel coil, oil-free or lightly oiled.

Coating type: GI, GA, GF; Weight: 60-600g/m2

Product quality: Conforms to GB/T2518-2008

Unit speed: Inlet Max200mpm, process section, Max150mpm, outlet section Max200mpm

Annual output: 200,000-400,000tpy

Energy saving methods: Waste gas heat recovery, SUNNY patent

Continuous annealing furnace: Oxidation-free heating (NOF) + radiant tube heating (RTF), horizontal or L-shaped

Fuel type: Natural gas, liquefied petroleum gas, mixed gas, coke oven gas

Welding equipment: Double-roll lap seam welder

Degreasing method: Chemical degreasing + electrolytic degreasing + three-stage water rinsing, horizontal (can be omitted)

Zinc pot type: Ceramic induction zinc pot

Air knife: SUNNY patent

Leveler: Four-roll wet leveling, large rolling force 6,000KN

Straightening machine: Two bends and one straightening

Passivation/Fingerprint resistance: Cr6+, Cr3+, inorganic passivation, roll coating

Oiling method: Electrostatic oiling

Electrical control system: SIEMENS or ABB AC frequency control system

Industrial automation: SIEMENS or ABB automation control system

Main process flow of the unit:

Uncoiling, welding, degreasing (optional), NOF reduction, galvanizing, (alloying), leveling, straightening, passivation/fingerprint resistance, electrostatic oiling, slitting, coiling

Wechat

Wechat