Weapons that use lasers to directly damage targets are known as laser weapons. Laser weapons are characterized by their high propagation speed, rapid fire transfer, recoil-free launch, high firing accuracy, high destructive power, and strong anti-jamming capabilities, making them lethal killers for aircraft and other weapons. Among the major military powers in the world, the United States is at the forefront of laser weapon research. In January 2009, it achieved an output of 105 kW, reaching the target of 100 kW output power, the third stage of laser weapon application. 100 kW power has always been regarded as the threshold for weapon-grade high-energy lasers, and high-energy laser weapons have gradually become an important means of striking anti-missiles, anti-satellites, anti-aircraft, and ground targets for various military powers.

As high-energy laser weapons gradually enter the practical application stage, research on laser protection technology has attracted much attention. Laser protection through material technology includes film-type, structural-type, and coating-type. Film-type mainly targets anti-laser protection for satellite optical systems and photoelectric sensors, mainly using the method of coating thin films on the surface of optics and sensors; structural-type mainly refers to achieving structural and functional integration through structural design to achieve laser protection, such as the design reported by the United States in 1998 for certain sensitive parts of aircraft as sheet metal plus metal mesh to achieve laser protection, the metal mesh can be designed as multi-layer according to needs; coating-type materials are the most traditional protective materials and materials for achieving special functions for aircraft. Because simple air spraying or brushing processes can be used for construction, it is one of the most cost-effective and applicable protective materials. However, because the coating materials that counteract lasers have extremely high requirements for material properties, the research on laser protection coating materials is a brand-new field both domestically and internationally. This work starts with the preparation process of general protective coatings, and through formula design and process optimization, high-performance anti-laser ablation coating materials have been prepared.

1. Experimental Materials and Methods

1.1 Coating Preparation

Using organosilicon resin and polycarbosilane as binders, fillers such as Al2O3, SiC, ZrO2, SiO2, BN, glass powder, and carbon fiber are added to form a mixed slurry. The mixed slurry is ground on a sand mill to a fineness of 40~50μm. Then, a coating is prepared on the surface of a 30CrMnSiA steel plate with dimensions of 50mm×100mm×2mm and a phosphated surface. The coating is prepared using a common air spraying method, with an air pressure of 0.4 MPa. The spray gun is provided by SATA, Germany, with a diameter of 0.8~1 mm. The specific spraying process is completed in several passes according to the required thickness, with one vertical cross-spraying considered as one pass. A certain time interval is required between each pass to achieve a certain degree of surface drying to prevent dripping. After spraying, it is left at room temperature for 48h, and then baked at 200℃ for 2h to cure the film.

1.2 Performance Characterization

The fully cured coating is first baked in a muffle furnace, heated from room temperature to 600℃, kept for 2h, and then cooled to room temperature with the furnace, in accordance with standard GB/T9286—1998. The adhesion of the paint film is tested using the cross-cut method, and the surface of the coating is observed with a stereomicroscope for initial performance evaluation. Then, it is ablated under oxy-acetylene, and the ablation morphology of the coating after ablation for 4s under different flame temperatures is observed. Finally, anti-laser ablation testing is performed under laser beam irradiation. The laser irradiation time is (4±0.2) s, and a thermocouple is welded on the back during laser irradiation to monitor the temperature rise process.

A K-type thermocouple made of nickel-chromium-nickel-silicon alloy is used, with a long-term temperature measurement limit of 1300℃. When the temperature is too high, causing the thermocouple to loosen or fall off from the back plate, the resulting temperature curve will show jitter. The various temperature curves in this work are all reliable measurements with the thermocouple welded firmly. The laser ablation test was conducted at the Chengdu Precision Optical Engineering Center, with a laser wavelength of 1064 nm and a power range of 101~4000 W.

2. Experimental Results and Analysis

2.1 Coating Temperature Resistance Test Results

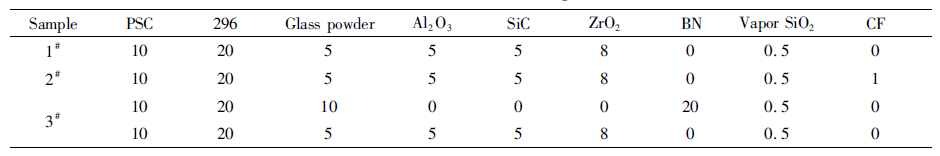

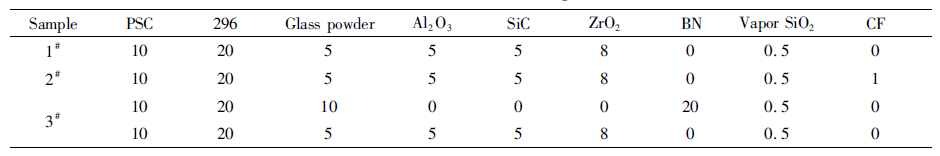

Coatings were prepared according to the formula shown in Table 1, with a total coating thickness of 40~50μm. Coating #3 has a double-layer structure, with different formulas for the upper and lower layers. The upper layer contains BN and its thickness is about 1/5 of the total thickness. It was placed in a 600℃ muffle furnace and kept for 2h. The condition of the coating after high-temperature heating is shown in Figure 1. According to the results shown in Figure 1, it can be seen that due to the addition of carbon fiber, the cracks in coating #2 are more obvious than those in coating #1 after heating, indicating that in the system with carbon fiber, the thermal stress of the coating increases.

In contrast, the surface cracks of coating #3 are significantly improved compared to coating #1 after heating. This is because during the heating process, the uniformly dispersed BN powder in the upper layer has good thermal conductivity, which can avoid local overheating of the paint film and also facilitates heat dissipation to the surrounding environment, alleviating thermal stress to a certain extent and improving the heat resistance of the paint film. At the same time, the addition of a larger amount of glass powder in the upper layer can also reduce the powdering phenomenon and enable better fusion between the upper and lower layers.

2.2 Coating Oxyacetylene Flame Ablation Test Results

Coatings were prepared according to the formula shown in Table 1, with a coating thickness of 500~600μm, and then simulated laser ablation for 4s using oxyacetylene flames of different temperatures. Figure 2 shows that after ablation, no significant changes occurred on the back of the substrate of coating #1, but deep cracks appeared around the ablation area.

After ablation at 2000℃, hills formed in the center of ablation (see Figure 3), while after ablation at 3000℃, a depression formed in the center of the hills. This is due to the effect of ZrO2 in the formula. ZrO2 is a typical phase-change ceramic. The low-temperature stable phase is monoclinic, which transforms into tetragonal at around 1000℃ and cubic at around 2370℃. During cooling from high temperature to low temperature, the reverse phase change occurs. From low temperature to high temperature, each phase change is accompanied by volume shrinkage, and from high temperature to low temperature, each phase change is accompanied by volume expansion. As the temperature of the coating in the ablation area increases, ZrO2 undergoes a phase change and volume shrinkage, so hills form in the center of the ablation. Because the specific heat and thermal conductivity of ZrO2 are relatively small, the surrounding area of the ablation area does not quickly heat up to the phase change temperature, resulting in deep ravines around the central area.

The ablation morphology of coating #2 is very similar to that of coating #1, except that the curling of the coating surface around the ablation area is more serious, indicating that the addition of carbon fiber did not play the expected strengthening role, but instead aggravated the shedding of the coating and reduced its adhesion performance.

After ablation of coating No. 3, no significant changes occurred on the back of the substrate. Compared with sample No. 1, the surface carbonization and blackening were severe, and a layer of easily detachable loose structure was covered (see Figure 6). This is because the BN in the upper layer undergoes significant oxidation when the temperature in the air reaches above 800℃, and the generated B2O3 begins to volatilize in large quantities in the gaseous state when the temperature reaches 1000℃, weakening the protective effect of the coating. On the other hand, although B2O3 can form a liquid film on the material surface, which hinders the penetration of oxygen into the material to a certain extent, according to literature reports, the compatibility between B2O3 and ZrO2 is not good, so it is difficult to effectively isolate oxygen.

Combining the high-temperature resistance test, it is not difficult to find that the addition of BN is a double-edged sword for improving the coating performance. On the one hand, the BN coating can effectively reduce the high-temperature cracking of the paint film and improve the high-temperature resistance of the coating; on the other hand, BN will reduce the ablation resistance of the coating. Therefore, in practical applications, the effects of these two aspects should be considered comprehensively, and the coating formula should be reasonably determined according to specific requirements.

2.3 Coating Laser Ablation Test Results

Based on the oxyacetylene flame simulated laser ablation results, coating No. 1 and blank steel plate were selected for laser ablation, and the results were compared to verify the anti-laser ablation performance of the coating with this formula. The coating thickness is 900~1000μm, and the irradiation parameters are given in Table 2.

As can be seen from Figure 7, under laser irradiation, the blank steel plate has obvious ablation damage zones on both the front and back sides, while the steel plate coated with coating No. 1 on the surface only has the front coating burned by the laser, and no obvious changes were found on the back side, indicating that the laser did not penetrate the coating to damage the substrate. This coating has excellent tolerance to laser irradiation and effectively protects the substrate. Figure 8 shows the temperature change curves on the back of the blank steel plate and the coated steel plate during ablation, which further confirms the anti-laser ablation effect of the coating. The two curves in the figure represent the temperature change on the back of the steel plate during ablation. The blank steel plate has no coating protection. After being irradiated by the laser, the temperature rises rapidly, and the peak temperature reaches 1387℃. After the irradiation stops, the temperature drops rapidly; while for the steel plate coated with coating No. 1, the temperature rises more slowly after being irradiated by the laser, and the peak temperature is 246℃. After the irradiation stops, the temperature decreases more slowly than the blank steel plate. It can be seen that the coating has a significant ablation-resistant and heat-insulating effect. With a thickness of 900~1000μm, the heat insulation effect on the surface of 1 mm thick 30CrMnSiA steel reaches more than 1000℃.

3. Conclusion

(1) An anti-laser ablation coating was prepared using organosilicon resin, polycarbosilane, and glass powder as binders, and adding Al2O3, BN, SiC, ZrO2, SiO2, and carbon fiber as heat-resistant fillers. The prepared coating has good anti-laser ablation and heat insulation performance.

(2) Within the thickness range of 900~1000μm, the prepared coating has a heat insulation effect of more than 1000℃ on the surface of 1 mm thick 30CrMnSiA steel under irradiation of 531 W/cm2 laser power density for 4 s.

(3) In the temperature range below 1000℃, BN can effectively improve the heat resistance of the coating and reduce the thermal cracking of the coating. In the high-temperature thermal ablation stage above 1000℃, the lower oxidation temperature of BN leads to the formation of a loose structure on the ablated surface, which cannot protect the substrate; while carbon fiber did not play the expected role of reinforcing the coating in the entire heating temperature range, but increased the tendency of the coating to crack and peel off under heat. ZrO2 with low thermal conductivity plays a key role in resisting laser ablation.

Wechat

Wechat