Coating preparation is the final process in the production of silicon steel. The type, process, and quality of the surface coating will significantly affect the insulation, adhesion, punching performance, and corrosion resistance of electrical steel, thereby affecting the specific total loss and other magnetic properties of the electrical steel itself, and even the key to whether the entire transformer can operate safely.

Oriented silicon steel, as an important magnetic material, has excellent properties of high magnetic induction and low iron loss, and is often widely used as the core material of power transformers.

Untreated electrical steel sheets will corrode and rust, not only affecting the performance of the silicon steel material itself, but also threatening the safe operation of the power grid. Generally, a very thin (0.5-5 μm) insulating coating is applied to the surface of the silicon steel sheet to give the silicon steel sheet a higher interlayer resistivity, minimizing interlayer power loss in the silicon steel sheet, and protecting the silicon steel sheet from various corrosive media during storage, transportation, and use, preventing rust.

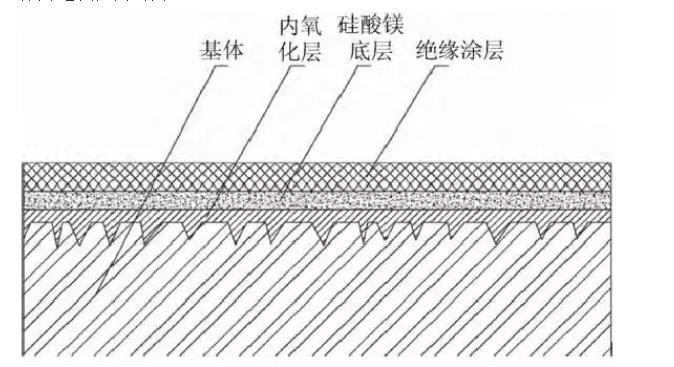

The magnesium silicate underlayer formed after high-temperature annealing of silicon steel has certain insulation and corrosion resistance, and at the same time produces tensile stress in the steel. Its interlayer resistance is greater than 4 Ω·cm²/sheet, which can meet the needs of distribution transformers with wound cores, but for medium and large transformers with laminated cores, its resistance is not large enough, and a layer of insulating coating must be applied to the surface. A schematic diagram of the surface cross-section of oriented silicon steel products is shown in Figure 1.

Figure 1 Schematic diagram of the surface cross-section of oriented silicon steel products

Coating preparation is the final process in the production of silicon steel. The type, process, and quality of the surface coating will significantly affect the insulation, adhesion, punching performance, and corrosion resistance of electrical steel, thereby affecting the specific total loss and other magnetic properties of the electrical steel itself, and even the key to whether the entire transformer can operate safely. This urgently requires the development of excellent insulating coating materials, which not only have good electrical insulation, coating adhesion, good shearing and punching processability and weldability, and corrosion and heat resistance, but can also withstand high-temperature annealing at 700-800℃, and at the same time have a high stacking factor and uniform surface color. Domestic and foreign research and improvement of coating technology are constantly being carried out to further improve the performance of oriented silicon steel products.

1. Overview of foreign research on oriented silicon steel coatings

Oriented silicon steel surface insulating coatings used in domestic and foreign research mainly include three categories: organic coatings, semi-inorganic coatings, and inorganic coatings. Organic coatings are more traditional insulating coatings in China, mainly including acrylic resins, vinyl acetate resins, modified alkyd resins, and epoxy resins. They are usually used in the manufacture of high-grade silicon steel for large motors. Organic coatings have good film-forming properties, good insulation and impact resistance, high shear punching performance and interlayer resistance, but low film hardness, large thermal shrinkage deformation, poor heat resistance and weldability, and are prone to creep after heating. As can be seen from Figure 2, as the content of organic resin in the coating increases, the punching performance improves, but the weldability decreases. However, in some special cases, the coating needs to be heat-treated at 600℃ before being used as an insulating coating. Most of the resins in the organic coating have degraded and volatilized at 600℃, losing their insulating capacity, and at the same time volatilizing harmful gases, causing environmental pollution, so that stress relief annealing cannot be performed. Currently, organic coatings are gradually being phased out.

Figure 2 Relationship between organic resin content and punching number and welding speed

In order to improve the adverse effect of large secondary grains on iron loss, Nippon Steel proposed a stress coating of ultrafine colloidal SiO2 added to phosphate solution. The stress coating produces isotropic tensile stress on the steel surface, reducing iron loss P and magnetostriction, and at the same time offsetting the adverse effects of external stress on silicon steel. Kawasaki uses a stress coating mainly composed of magnesium phosphate (Mg(H2PO4)2) with colloidal SiO2 and CrO3 added, which improves the moisture absorption resistance of the coating and also improves the appearance. However, chromium compounds contain hexavalent Cr, which pollutes the environment and makes waste liquid treatment troublesome. Nippon Steel also proposed the use of solid-solution composite metal hydroxides with an average particle size of less than 1 μm or 2-3 μm, plus borates, acetates, and silicates, which have good adhesion, corrosion resistance, and sintering resistance, but poor moisture absorption resistance and heat resistance. Adding fine particulate colloidal oxides can react with free phosphoric acid to form more stable phosphate compounds, thereby improving moisture absorption resistance and heat resistance, and also improving lubricity. To prevent the aggregation of particulate colloidal oxides, organic acid salts are added, but the coating liquid is unstable. Inorganic compounds such as ultrafine particles of Fe(OH)2 of about 10 nm are added to adjust the structure of the colloidal oxide, making the phosphate solution more stable.

Semi-inorganic coatings are insulating coatings formed by mixing phosphate and chromate inorganic solutions with latex resin solutions. Organic resin powder particles with a particle size of 2-50 μm are added to the latex resin, and then mixed with the inorganic solution and coated on the surface of silicon steel for baking. The inorganic component of traditional semi-inorganic coatings is chromate, which has good corrosion resistance. Organic resin powder particles are usually one or several polymers or mixtures of polyethylene, polypropylene, polyphthalamide, benzidine triazole, polypropylene resin, or polyphenylene ethene, among which the polyphenylene ethene copolymer has the best viscosity strength.

Nippon Steel first proposed the tension coating in 1973, the main component of which is ultrafine colloidal SiO2 (silicon sol) added to the phosphate coating solution. The tensile stress generated by the coating can refine the magnetic domains, effectively reducing iron loss and magnetostriction. Relevant studies have shown that by adjusting the coating formula and using appropriate drying and sintering processes, the iron loss P1.7 can be reduced by as much as 0.1 W/kg.

In order to reduce the iron loss of oriented silicon steel, one of the most effective methods is to develop new coating technologies. Research results show that the magnesium oxide coating has an important influence on the magnetic and surface properties of oriented silicon steel. In addition, Japan has adopted chemical vapor deposition to coat thin films, forming ceramic insulating films instead of forsterite films, using laser processing and changing the type of inorganic acid in the insulating film coating liquid to reduce iron loss. The results show that by improving the composition of the insulating film coating liquid, improving the viscosity stability and film tension, oriented silicon steel sheets with high magnetic induction and low iron loss can be obtained.

At present, foreign countries have made certain progress in the research field of environmentally friendly coating new technologies, but satisfactory results have not yet been obtained in terms of ensuring the comprehensive performance of insulating coatings.

2. Research Status of Surface Coatings for Grain-Oriented Silicon Steel in China

In the 1940s, hot-rolled silicon steel used insulation paint on its surface. This method was still used in China until the 1980s, even applying insulation paint over cold-rolled silicon steel with existing glass coatings. Early research in China mainly focused on pure organic coatings; however, due to their low hardness and poor heat resistance, they are rarely used by domestic silicon steel companies now.

Later, companies in the United States and Japan successively developed phosphate surface coatings with better insulation properties. However, previous coatings generally contained chromates to improve corrosion resistance and interlayer resistance. For a long time, almost all cold-rolled silicon steel production in China used insulation coating materials containing hexavalent chromium. There are no clear standards regarding environmental issues related to insulation coatings; water-based chromium-free silicon steel coatings, using water as the main solvent, are generally considered environmentally friendly coatings. However, these inorganic coatings are subject to various constraints in practical applications, and semi-inorganic coatings are still mainly used in China. The semi-inorganic insulation coatings used by domestic steel enterprises are mainly shown in Table 1.

Table 1 Coating Codes and Classifications of Major Electrical Steel Manufacturers in China

In the production process of grain-oriented silicon steel, to prevent the steel plates from sticking together during annealing, magnesium oxide (MgO) needs to be applied to the surface of the steel plates before high-temperature annealing. During the annealing process, MgO reacts with the oxide layer on the surface of the steel plate to form a magnesium silicate underlayer. Then, a phosphate tension coating is applied to the outer surface, forming a double-layer structure of a magnesium silicate underlayer and a phosphate coating. Due to the different thermal expansion coefficients, the phosphate coating will exert tension on the substrate after high-temperature cooling, which is the tension coating. The thermal expansion coefficient of the magnesium silicate underlayer is between that of the steel plate and the phosphate coating, which is beneficial to the adhesion of the phosphate coating and the exertion of its tension. Hu Shutian et al. used chemical methods to remove the surface phosphate coating and magnesium silicate underlayer of grain-oriented silicon steel separately to study the coating structure and its impact on core loss. The research results are shown in Table 2.

Table 2 Iron Loss of Grain-Oriented Silicon Steel Sheets with Different Coating Structures

The results in Table 2 show that the phosphate coating can reduce the iron loss of grain-oriented silicon steel by about 9%. The embedded structure of the magnesium silicate underlayer gives the coating good adhesion but has an adverse effect on the core loss of grain-oriented silicon steel. Based on the synergistic effect of the two layers, eddy current loss during core use can be effectively reduced. The surface tension provided can also reduce noise and loss caused by magnetostriction and domain wall movement during core use.

3. Development Direction of Silicon Steel Surface Insulation Coatings

The core loss, magnetostriction, and other properties and surface quality of grain-oriented silicon steel are closely related to the surface insulation coating. The tensile stress generated by the coating on the silicon steel sheet can offset the compressive stress generated during transformer assembly, thereby reducing transformer noise. Due to the coating, the stress sensitivity of the steel sheet during magnetostriction is weakened, and the transformer noise is also reduced. At the same time, the insulation coating of grain-oriented silicon steel sheets has the effect of reducing specific total loss, and the iron loss can be reduced by 9%-14%. Research and application of high-performance silicon steel surface insulation coatings have a significant impact on improving the comprehensive performance of grain-oriented silicon steel.

Hexavalent chromium causes serious harm during the production and use of coatings and the discharge of waste liquid. Although semi-inorganic coatings have improved some shortcomings of inorganic and organic coatings and are currently the most widely used, some of the volatile organic solvents they contain are also toxic. It is necessary to minimize or eliminate the use of volatile organic solvents. The development of high-performance inorganic coatings is a research focus for insulation coatings. Therefore, chromium-free, environmentally friendly, inorganic insulation coatings for grain-oriented silicon steel are the key development direction for grain-oriented silicon steel insulation coatings.

4. Conclusion

1. Surface insulation coatings can reduce iron loss, weaken the sensitivity of magnetostriction to stress, and reduce transformer noise. It is an important process in the production of grain-oriented silicon steel.

2. The surface insulation coatings used in domestic and foreign research for grain-oriented silicon steel mainly include three categories: organic coatings, semi-inorganic coatings, and inorganic coatings. Organic coatings have been eliminated, and inorganic coatings will gradually replace semi-inorganic coatings.

3. To meet environmental requirements, research and improvement of chromium-free, environmentally friendly inorganic coatings that do not contain volatile organic components is the development direction of silicon steel surface insulation coatings.

Wechat

Wechat