Solutions

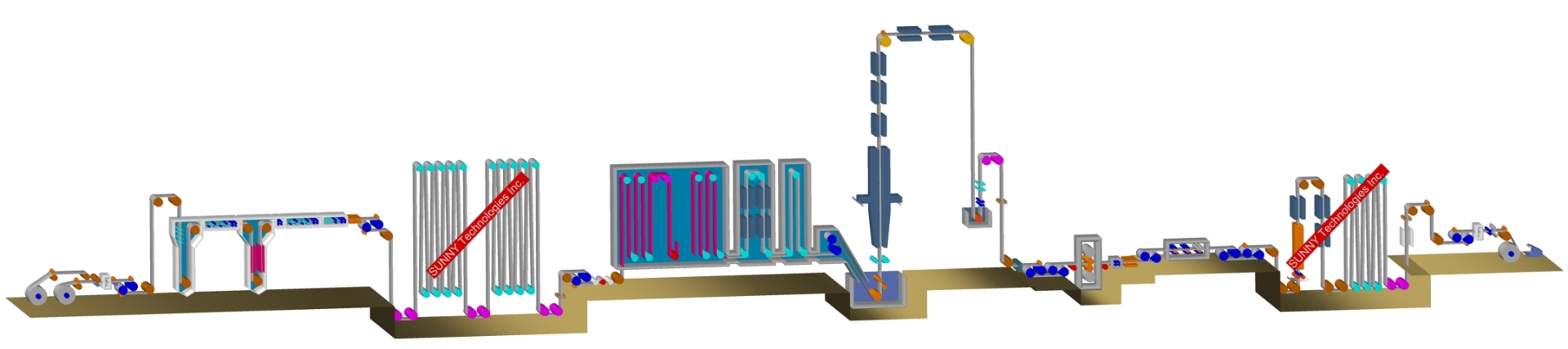

Continuous Galvanized Steel Sheet Production Line (GL)

Category: Solution

Galvanized aluminum zinc silicon (GL) products are produced by hot-dipping steel strip in an aluminum (Al 55%), zinc (Zn 43.5%), and silicon (Si 1.5%) alloy. They exhibit excellent corrosion resistance. Hot-dip aluminum zinc alloy is developed based on hot-dip aluminum and hot-dip galvanizing technologies. It combines the excellent atmospheric corrosion resistance and heat/oxidation resistance of aluminum-coated products with the excellent electrochemical protection of galvanized steel products, making cut and scratched areas less susceptible to corrosion and rust.

Details

Galvanized aluminum-zinc-silicon (GL) products are produced by hot-dipping steel strips in an aluminum (Al55%), zinc (Zn43.5%), and silicon (Si1.5%) alloy. They exhibit excellent corrosion resistance.

Hot-dipped aluminum-zinc alloy is developed based on hot-dipped aluminum and hot-dipped zinc technologies. It combines the excellent atmospheric corrosion resistance and heat resistance/oxidation resistance of aluminum-coated products with the excellent electrochemical protection of galvanized steel products, making it less susceptible to corrosion and rust at cuts and scratches.

Its main advantages are as follows:

(1) Smooth surface, with excellent atmospheric corrosion resistance. Its corrosion resistance is 2-6 times higher than that of hot-dip galvanized steel sheet;

(2) Excellent heat resistance and oxidation resistance. It remains unchanged in color at 300℃ for a long time and can be used for a long time at around 500℃. It has good water and soil corrosion resistance. Its water corrosion resistance is superior to hot-dip galvanized and hot-dip aluminum sheets, and its soil corrosion resistance is superior to hot-dip galvanized sheets. It is an ideal material for making corrosion-resistant parts such as automotive mufflers, exhaust pipes, grain dryers, and water heaters; in addition, the product's thermal reflectivity is higher than 75%, which is twice that of galvanized steel sheets;

(3) Excellent paintability and good processability. It has strong bonding strength to organic materials and is the best choice for substrates of color organic coated steel sheets. Its processability and weldability are similar to hot-dip galvanized sheets. It can be cold-bent, stamped, and has a good appearance.

Main characteristics of the unit:

Raw materials: Cold-rolled low-carbon steel SPCC, SPCD, 600-1550mm x 0.2-1.2 (1.5) mm, conforming to JISG3141

Coating type: GL; Weight: 60-300g/m2

Product quality: Conforms to Q/BQB425-2004

Unit speed: Inlet 0-260 mpm, process section 0-200 mpm, outlet section 0-260 mpm

Annual output: 100,000-300,000 tpy

Energy saving method: Waste gas heat recovery, SUNNY patent

Continuous annealing furnace: NOF + radiant tube heating RTF, full radiant tube heating (RTF), vertical, horizontal or L-type furnace

Fuel type: Natural gas, liquefied petroleum gas, mixed gas, coke oven gas and electricity

Welding equipment: Narrow lap seam welder

Degreasing method: Chemical degreasing + electrolytic degreasing + three-stage water rinsing, vertical or horizontal

Zinc pot type: Ceramic induction zinc pot: pre-melting pot + main pot

Air knife: SUNNY patent

Leveling machine: Four-roll wet leveling, maximum rolling force 4,000 KN

Straightening machine: Two bends and one straightening, two bends and two straightening

Passivation/fingerprint resistance: Roll coating type

Oiling method: Electrostatic oiling

Electrical system: SIMENS/ABB PLC, AC frequency conversion automatic control system

Automation instruments: SIMENS/ABB PLC, intelligent automatic control system

Main process flow of the unit:

Uncoiling, welding, degreasing, annealing reduction, aluminum-zinc plating, controlled cooling, leveling, straightening, passivation/fingerprint resistant coating, etc.

Wechat

Wechat