Solutions

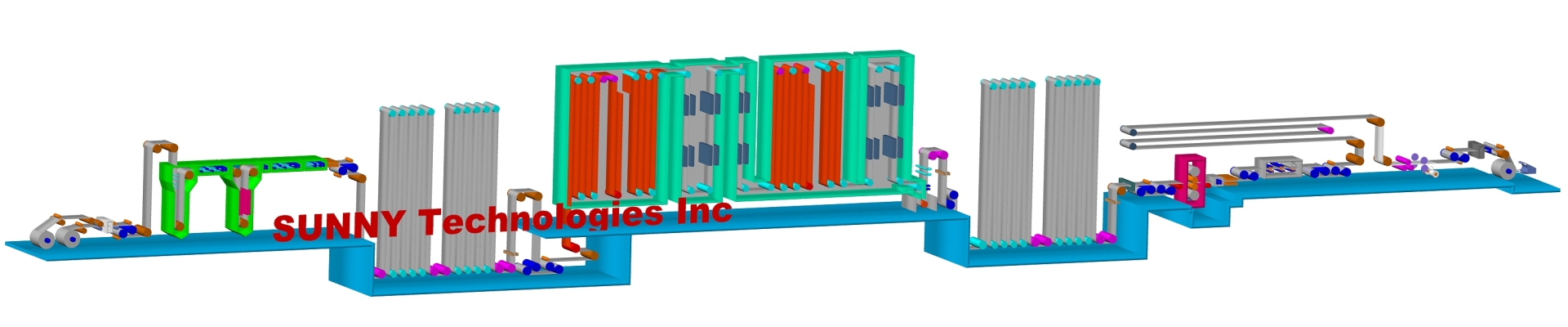

Continuous Annealing Line (CAL)

Category: Solution

Annealing steel strip is to homogenize the chemical composition and structure of the steel, refine the grain size, adjust the hardness, eliminate internal stress and work hardening, and improve the forming processability of the steel. Continuous annealing is a process in which the steel strip is heated to an appropriate temperature under a protective atmosphere and held for a certain period of time, followed by cooling and overaging treatment. In order to improve the surface quality of the strip, an online leveling machine is generally designed.

Details

Steel strip annealing is to homogenize the chemical composition and microstructure of the steel, refine the grain size, adjust the hardness, eliminate internal stress and work hardening, and improve the formability of the steel.

Continuous annealing is a process in which the steel strip is heated to an appropriate temperature under a protective atmosphere, held for a certain time, and then cooled and over-aged. In order to improve the surface quality of the strip, an online leveling machine is generally designed.

Main characteristics of the unit:

Raw materials: Steel strip: Width: 600-1550mm, Thickness: 0.2-1.2 (1.5) mm

Material: Cold-rolled steel coils SPCC, SPCD, SPCE, conforming to JISG3141

Product quality: CQ, DQ and DDQ, conforming to JISG3141

Unit speed: Inlet 0-240 mpm, process section 0-180 mpm, outlet section 0-240 mpm

Annual output: 100,000-300,000 tpy

Energy saving method: Waste gas heat recovery, SUNNY patent

Continuous annealing furnace: Full radiant tube heating (RTF), vertical

Fuel type: Natural gas, liquefied petroleum gas, mixed gas, coke oven gas and electricity

Welding equipment: Narrow lap seam welder

Degreasing method: Chemical degreasing + electrolytic degreasing + three-stage water rinsing, vertical or horizontal

Leveler: Four-roll wet leveling, maximum rolling force 6,000 KN

Straightening machine: Two bends and two straightening (Optional)

Oiling method: Electrostatic oiling

Electrical control system: SIEMENS or ABB AC frequency control system

Automation instruments: SIEMENS or ABB automation control system

Main process flow of the unit:

Uncoiling → Welding → Degreasing (alkaline washing + alkaline brushing + electrolysis + water washing + water cleaning) → Annealing reduction (heating → homogenization → rapid cooling → overaging → secondary cooling → water quenching → drying) → Leveling → Straightening → Edging → Inspection → Oiling → Slitting → Coiling

Wechat

Wechat