SOLUTION

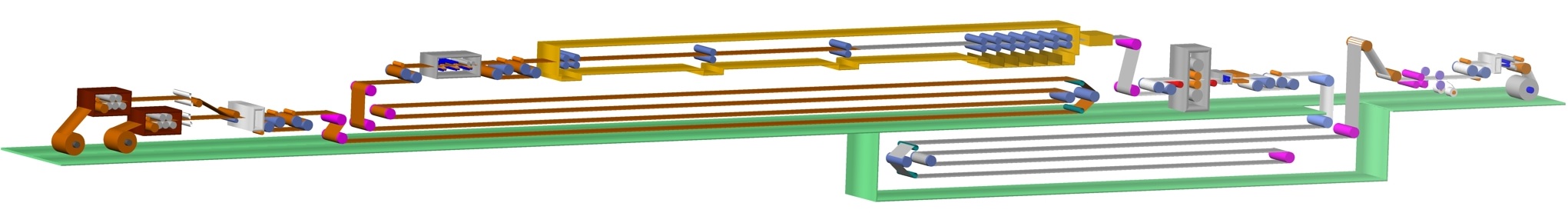

Carbon Steel Continuous Pickling Unit (CPL)

Unit characteristics

Continuous pickling unit, with automatic argon arc welding machine and Polin pull straightening machine at the entrance, hydrochloric acid multi-stage shallow groove turbulent pickling process and multi-stage water rinsing process in the process section, disc cutter and electrostatic oiling machine at the outlet section Wait.

Annual production scale: 800,000-1,200,000t/a

Raw material: carbon steel hot rolled coil

Steel grade: CQ, DQ, DDQ, IF, HSLA, W440-W1300 silicon steel

Raw material specifications: 1.5-6.0mmx width: 650-1650mm

Roll diameter: I.D.Φ760/Φ610mmO.D.MaxΦ2150mm Maximum roll weight: 30t

Hot rolled coiling temperature: Max670 degrees (IF<720 degrees)

Process speed: Max150mpm

Pickling time: 25-30sec

adopt SIEMENS or ABB electrical control system

Production process

Recommended products

黄石山力科技股份有限公司

Sunny Technologies Incorporation Limted

Contact us

Add:No. 2, Guangzhou road, tuanshancheng Development Zone, Huangshi City, No. 101, Gaoxin 6th Road, Donghu New Technology Development Zone, Wuhan

Mail:spt@sunnychina.com.cn

Tel:156 7177 7755 / 027-59715061

Fax:027-59715060