NEWS CENTER

Development and performance characterization of high temperature and laser ablation resistant coatings

- Time of issue:2018-11-30 18:16

(Summary description)Weapons that use the direct irradiation of lasers to kill targets are called laser weapons. Laser weapons have the characteristics of high transmission speed, fast transfer of firepower, recoilless launch, high launch accuracy, high lethality, and strong anti-interference ability. They have become the deadly killer of various weapons such as aircraft. Among the major military countries in the world, the United States is at the forefront of laser weapon research. In January 2009, an output of 105kW was achieved, reaching the target of 100kW output power in the third stage of laser weapon application.

Development and performance characterization of high temperature and laser ablation resistant coatings

(Summary description)Weapons that use the direct irradiation of lasers to kill targets are called laser weapons. Laser weapons have the characteristics of high transmission speed, fast transfer of firepower, recoilless launch, high launch accuracy, high lethality, and strong anti-interference ability. They have become the deadly killer of various weapons such as aircraft. Among the major military countries in the world, the United States is at the forefront of laser weapon research. In January 2009, an output of 105kW was achieved, reaching the target of 100kW output power in the third stage of laser weapon application.

- Categories:Industry News

- Author:

- Origin:Corrosion News

- Time of issue:2018-11-30 18:16

- Views:

Weapons that use the direct irradiation of lasers to kill targets are called laser weapons. Laser weapons have the characteristics of high transmission speed, fast transfer of firepower, recoilless launch, high launch accuracy, high lethality, and strong anti-interference ability. They have become the deadly killer of various weapons such as aircraft. Among the major military countries in the world, the United States is at the forefront of laser weapon research. In January 2009, an output of 105kW was achieved, reaching the target of 100kW output power in the third stage of laser weapon application. 100kW power has always been regarded as the threshold for weapon-grade high-energy lasers. High-energy laser weapons have gradually become an important means of combating military powers’ anti-missile, anti-satellite, anti-aircraft and ground targets.

As high-energy laser weapons gradually enter the actual combat application stage, laser protection technology research has attracted much attention. Laser protection through material technology includes thin films, structures and coatings. The film type is mainly for the anti-laser protection of satellite optical systems and photoelectric sensors, mainly using the method of coating the surface of the optics and the sensor; the structure type mainly refers to the integration of structure and function through structural design to achieve the purpose of laser protection, such as the United States in 1998 It is reported that some sensitive parts of the aircraft are designed as a sheet plus a metal mesh to achieve laser protection. The metal mesh can be designed as multiple layers according to requirements; coating materials are the most traditional form of protection and special functions for aircraft, because they can be used Simple air spraying or brushing process for construction, so it is one of the most suitable protective materials with the lowest application cost. However, due to the extremely high requirements for the material performance of the laser-resistant coating materials, the laser protective coating material technology research is at home and abroad All belong to a completely new field. This work started with the preparation process of general protective coatings, and through formulation design and process optimization, a coating material with excellent performance was prepared for laser ablation resistance.

1. Experimental materials and methods

1.1 Coating preparation

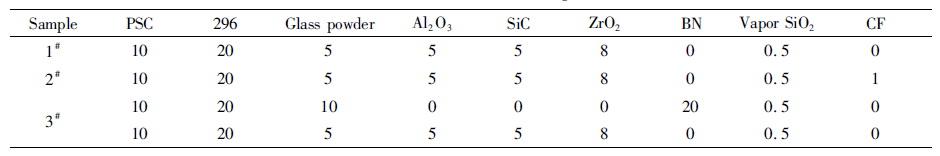

Use silicone resin and polycarbosilane as binder, add Al2O3, SiC, ZrO2, SiO2, BN, glass powder, carbon fiber and other fillers to form a mixed slurry. The mixed slurry is ground on a sand mill to a fineness of 40-50μm . Then, a coating is prepared on the surface of a 30CrMnSiA steel plate with a size of 50mm×100mm×2mm and a phosphating treatment on the surface. The coating preparation adopts the ordinary air spraying method, the air pressure is 0.4MPa, the spray gun is provided by the German SATA company, and the caliber is 0.8-1mm. The specific spraying process is divided into several passes according to the required thickness. The vertical cross spraying is regarded as one pass. A certain time interval is required between each pass to achieve a certain degree of surface drying and prevent flow. After spraying, leave it at room temperature for 48 hours, and then bake at 200°C for 2 hours to solidify into a film.

1.2 Performance characterization

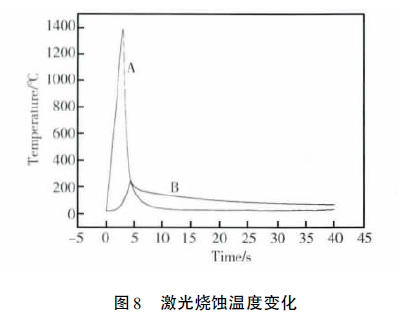

The cured coating is first baked in a muffle furnace, heated from room temperature to 600°C, kept for 2 hours, and cooled to room temperature with the furnace, referring to the standard GB/T9286-1998. The cross-hatch method was used to test the adhesion of the paint film, and the coating surface was observed with a stereo microscope for preliminary performance evaluation. Then ablate under oxygen-acetylene to observe the ablation morphology of the coating after ablation for 4s at different flame temperatures. Finally, an anti-laser ablation test was carried out under laser beam irradiation. The laser irradiation time was (4±0.2) s. During the laser irradiation, a thermocouple was welded on the back to monitor the temperature rise process.

The thermocouple uses a nickel-chromium-nickel-silicon alloy K-type thermocouple, and the long-term temperature measurement limit is 1300℃. When the temperature is too high and the connection between the thermocouple and the backplane becomes loose or falls off, the resulting temperature curve will jitter. The various temperature curves in this work are reliable and reliable measurements for thermocouple welding. The laser ablation test was carried out in Chengdu Precision Optical Engineering Center. The laser wavelength was 1064nm and the power range was 101~4000W.

2. Experimental results and analysis

2.1 Coating temperature resistance test results

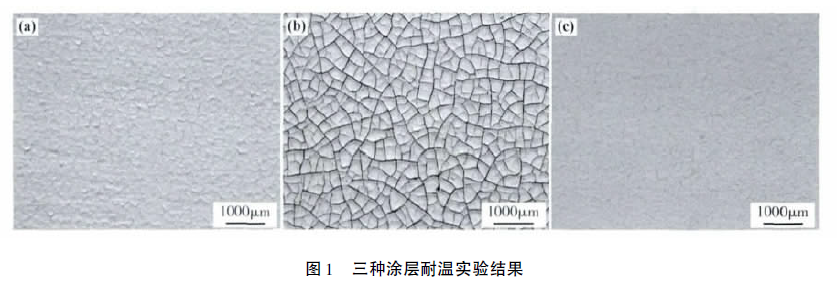

Prepare the coating according to the formula shown in Table 1, the total thickness of the coating is 40-50μm, of which the 3# coating is a two-layer structure, and the upper and lower layers use different formulas. The upper filler contains BN and the thickness is about 1/5 of the total thickness. Placed in a 600 ℃ muffle furnace for 2 hours, the coating condition after high temperature heating is shown in Figure 1. According to the results shown in Figure 1, it can be seen that due to the addition of carbon fiber, the 2# coating has more obvious cracks after heating than the 1# coating, indicating that the thermal stress of the coating increases in the system with carbon fiber.

In contrast, 3# coating compared with 1# coating, the surface cracks are significantly improved after heating. This is because during the heating process of the double-layer structure, the evenly dispersed BN powder on the upper layer has good thermal conductivity, which can avoid local overheating of the paint film, and at the same time, it is also conducive to heat dissipation to the surrounding environment, which relieves the thermal stress to a certain extent and improves the paint. Film heat resistance. At the same time, the upper layer of glass powder is added more, which can also reduce the pulverization phenomenon and make the upper and lower layers better merge.

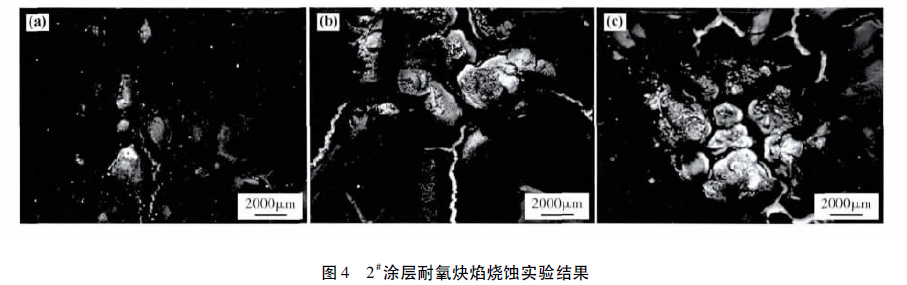

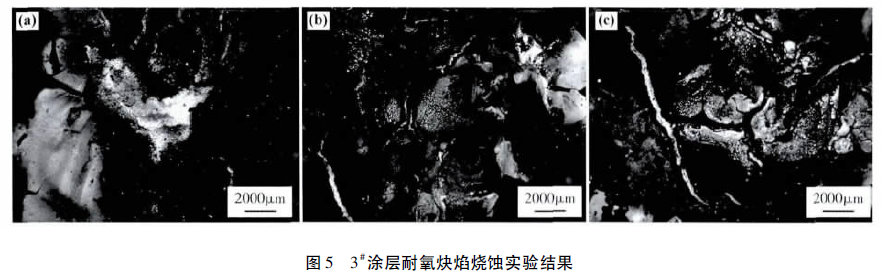

2.2 Test results of coating resistance to oxyacetylene flame ablation

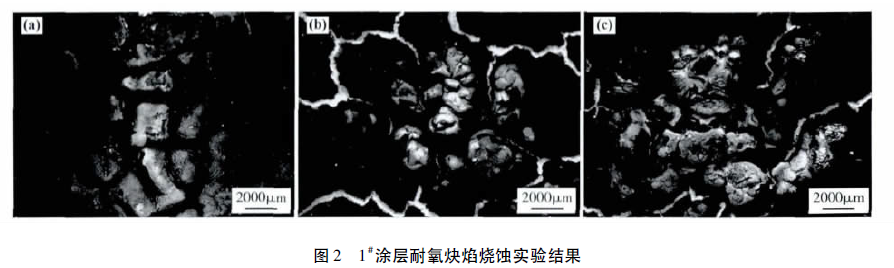

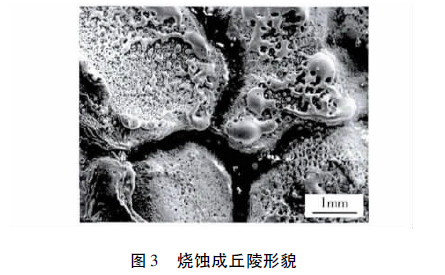

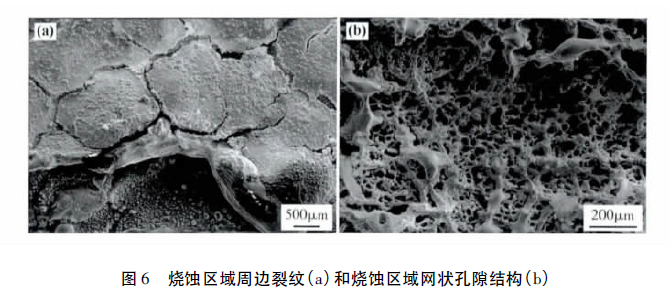

Prepare the coating according to the formula shown in Table 1, with a coating thickness of 500-600 μm, and then simulate laser ablation with oxyacetylene flames at different temperatures for 4 seconds. It can be seen from Figure 2 that there is no obvious change in the back of the substrate after the ablation of the 1# coating, but deep cracks appear around the ablation area.

2.3 Coating laser ablation resistance test results

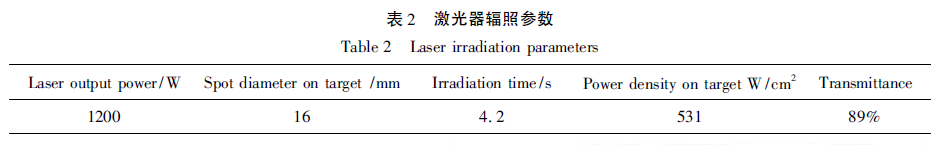

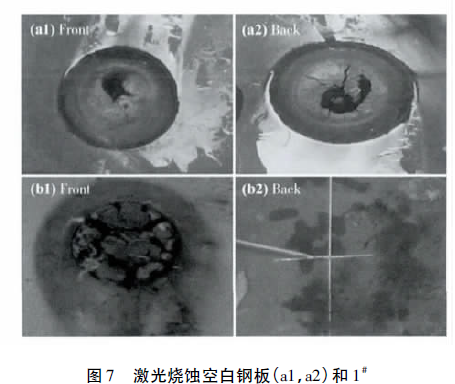

According to the results of oxyacetylene flame simulation laser ablation, 1# coating and blank steel plate were selected for laser ablation, and the results were compared to verify the laser ablation resistance of the coating. The coating thickness is 900~1000μm, and the irradiation parameters are given in Table 2.

3. Conclusion

(1) Using silicone resin, polycarbosilane and glass powder as binders, adding Al2O3, BN, SiC, ZrO2, SiO2 and carbon fiber and other heat-resistant fillers to prepare anti-laser ablation coatings, the prepared coatings have good properties Resistance to laser ablation and heat insulation.

(2) The prepared coating is in the thickness range of 900~1000μm, irradiated for 4s under the laser power density of 531W/cm2, and the heat insulation effect on the surface of 1mm thick 30CrMnSiA steel reaches above 1000℃.

(3) In the temperature range below 1000°C, BN can effectively improve the heat resistance of the coating and reduce thermal cracking of the coating. In the high temperature thermal ablation stage above 1000°C, the lower oxidation temperature of BN leads to its ablated surface The formation of a loose structure can not protect the substrate; and the carbon fiber does not play a role in reinforcing the coating during the entire heating temperature range, but increases the tendency of the coating to crack and fall off. ZrO2 with low thermal conductivity plays a key role in the fight against laser ablation.

Hot News

黄石山力科技股份有限公司

Sunny Technologies Incorporation Limted

Contact us

Add:No. 2, Guangzhou road, tuanshancheng Development Zone, Huangshi City, No. 101, Gaoxin 6th Road, Donghu New Technology Development Zone, Wuhan

Mail:spt@sunnychina.com.cn

Tel:156 7177 7755 / 027-59715061

Fax:027-59715060