NEWS CENTER

High-precision rolling and heat treatment process and equipment technology of thin strip steel

- Time of issue:2018-12-13 02:26

(Summary description)The article introduces a high-precision rolling and heat treatment process and equipment technology of Bosteel. It is based on the previous work in the advanced cold-rolling direction to continuously improve the control accuracy of the high-precision cold-rolled flatness control system and promote its popularization and application. Carried out the research and application of edge thinning control technology; in terms of advanced continuous annealing and coating technology, we continue to promote direct flame impingement rapid heating technology, non-oxidation rapid cooling technology, and hot-dip galvanizing quality control technology research and development, and carry out The research, popularization and application of the warm rolling process and equipment technology of cast-rolled thin strip.

High-precision rolling and heat treatment process and equipment technology of thin strip steel

(Summary description)The article introduces a high-precision rolling and heat treatment process and equipment technology of Bosteel. It is based on the previous work in the advanced cold-rolling direction to continuously improve the control accuracy of the high-precision cold-rolled flatness control system and promote its popularization and application. Carried out the research and application of edge thinning control technology; in terms of advanced continuous annealing and coating technology, we continue to promote direct flame impingement rapid heating technology, non-oxidation rapid cooling technology, and hot-dip galvanizing quality control technology research and development, and carry out The research, popularization and application of the warm rolling process and equipment technology of cast-rolled thin strip.

- Categories:Industry News

- Author:

- Origin:轧钢之家

- Time of issue:2018-12-13 02:26

- Views:

The article introduces a high-precision rolling and heat treatment process and equipment technology of Bosteel. It is based on the previous work in the advanced cold-rolling direction to continuously improve the control accuracy of the high-precision cold-rolled flatness control system and promote its popularization and application. Carried out the research and application of edge thinning control technology; in terms of advanced continuous annealing and coating technology, we continue to promote direct flame impingement rapid heating technology, non-oxidation rapid cooling technology, and hot-dip galvanizing quality control technology research and development, and carry out The research, popularization and application of the warm rolling process and equipment technology of cast-rolled thin strip.

High-precision rolling of thin strip steel

And heat treatment process and equipment technology

Preface

Advanced cold rolling, heat treatment and coating process and equipment technology are the key to the production of high-end cold rolled steel products. Since the center was approved, the advanced cold rolling direction has continuously improved the control accuracy of the high-precision cold-rolled flatness control system and promoted its popularization and application on the basis of the previous work, and carried out the research, popularization and application of edge thinning control technology; In terms of advanced continuous annealing and coating technology, we continue to advance the research and development of direct flame impingement rapid heating technology, non-oxidation rapid cooling technology and hot-dip galvanizing quality control technology, and carry out the research and application of warm rolling technology and equipment technology for cast-rolled thin strip Wait for work.

Main research progress

2.1 High-precision cold-rolled flatness and edge thinning control technology

High-precision cold-rolled flatness and edge thinning control technology is the core technology to ensure the quality of cold-rolled strip steel. Independent research and development of high-precision cold-rolled flatness and edge thinning control and equipment technology is of great significance for improving my country's core competitiveness in the field of rolling technology.

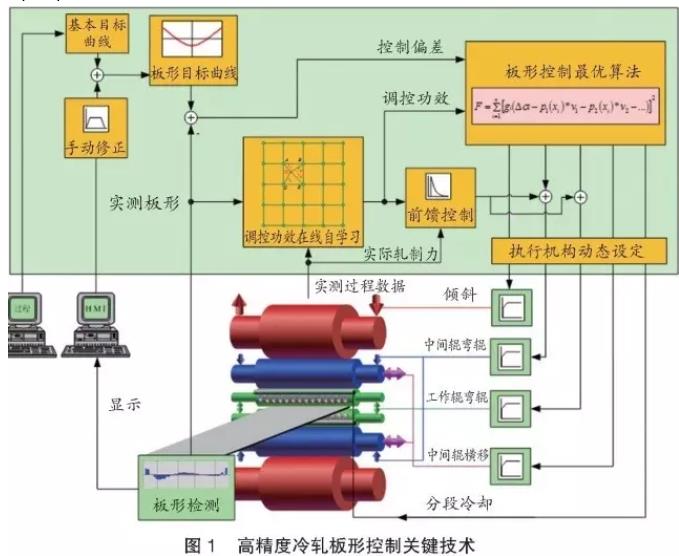

Modern mainstream flatness control cold rolling mills usually have multiple flatness adjustment mechanisms involved in flatness closed-loop feedback control, which makes their control digital and analogue systems more complex. Different from the pattern recognition method based on orthogonal decomposition, RAL is based on the independent research of the influencing efficiency function theory, through the numerical analysis method to construct the rolling mill tilt, work roll bending, intermediate roll bending, intermediate roll shifting and other flatness control execution The impact efficiency function of the device. The shape control evaluation function is constructed by the shape control actuator affecting the efficiency, the deviation between the actual measured value and the target value, the shape control influencing factor and the adjustment amount of each actuator of the shape control, and the evaluation function is calculated by the optimization method. The minimum value of each actuator adjustment under the minimum condition is used as the output value of a closed-loop control, so as to realize the multi-variable optimal shape control (Figure 1).

Flatness closed-loop feedback control uses the control efficiency coefficients of each flatness adjustment mechanism and the measured flatness value of each measurement section of the flatness roll, and uses the principle of linear least squares to establish the shape control effect evaluation function to solve the optimization of each flatness adjustment mechanism Adjustment amount. In view of the importance of the shape control efficiency coefficient in the shape control system, a self-learning model of the shape control effect was formulated. In order to obtain accurate shape control efficiency coefficients, artificial intelligence methods such as neural networks are used to continuously improve the accuracy of these prior values based on the measured shape data.

The RAL cold rolling flatness control system has a series of proprietary technologies, which are mainly reflected in the following aspects: The online self-learning model of flatness control efficiency coefficients has been developed, which is suitable for the flatness of any strip specifications, materials, and rolling mill models. The control process improves the versatility of the control system; a multi-variable optimal shape optimization method based on dynamic constrained convex quadratic programming is developed, without the need to solve the objective function gradient and Hesse matrix, and the objective function is not required to be continuously differentiable; the shape is introduced The dynamic alternative control mechanism of the adjustment mechanism solves the problem of flatness control when the actuator is saturated, and opens up new ideas for the in-depth study of flatness control technology; developed a work roll segmented cooling control based on fuzzy control, which does not rely on mathematics The model solves the nonlinear and time-varying large lag problems that are difficult to solve by conventional control.

The successful development of RAL cold-rolled flatness control technology has formed a unique technical system in the field of international cold-rolled strip steel production, and formed a control system with completely independent intellectual property rights and a core technology system for process control. The actual application has achieved tremendous results. Economic benefits. As of the end of 2016, high-precision cold-rolled flatness control technology has been used in 11 sets of cold-rolling units including Angang Putian 1450mm tandem cold rolling mill, Angang Tiantie 1800mm tandem cold rolling mill, Swincord 1450mm tandem cold rolling mill, and Shandong Guanzhou 1450mm tandem cold rolling mill. It has been promoted and applied, which greatly meets the increasingly higher quality requirements of subsequent units and users.

In terms of edge thinning control technology, in Angang's 1500mm silicon steel cold rolling mill, UCM was transformed into a single-end taper work roll shifting function UCMW tandem cold rolling mill. On this basis, the edge thinning process control model and self-adaptive automatic control system of multi-standard strip products such as work roll shifting, speed, roll bending force, etc. have been developed, which greatly reduces the quality requirements for the crown quality of the hot rolled material. , The edge thinning control is further improved, the 2σ value is less than 3.15μm, the cold-rolled product quality and the yield rate are improved by 2.7%, and the control precision and product quality of silicon steel thin strip edge thinning are greatly improved. In 2016, the "Cold-rolled Silicon Steel Edge Thinning Control Core Technology Research and Industrial Application" project jointly completed by Angang, Northeastern University and other units won the first prize of the 2016 Metallurgical Science and Technology Award.

2.2 Advanced continuous annealing and coating technology

With the increasingly stringent requirements of the market on the performance and quality of cold-rolled products, the existing key technologies of continuous annealing and coating are in urgent need of breakthroughs. High-efficiency and low-cost heating and cooling technologies are important breakthrough directions. The advanced cold rolling direction has made important progress in direct flame impact (DFI) rapid heating technology, non-oxidation rapid cooling technology, and hot-dip galvanizing quality control technology research and development, laying a solid foundation for further industrial applications. The specific progress is as follows:

1) Aiming at the problems of existing DFI technology, developed narrow-pitch multi-flame burners, flame pulse combustion control technology and flame width control technology with independent intellectual property rights. The pulse combustion control system is greatly simplified, the cost is reduced, and the flame width control method and device are simple and reliable; for the self-developed burner, the finite element simulation research and experiment on its combustion efficiency, flame characteristics, heating rate, pollution emission and other issues are carried out Research, optimize the burner structure and combustion process parameters, and obtain flame characteristic data (Figure 4). The heating rate of the thin plate reaches 180℃/(s·mm). By adjusting the air-fuel ratio, the oxidation degree of the strip surface is controlled to heat the DFI. The system design lays the foundation; on this basis, the DFI heating furnace (Figure 5) and the corresponding workpiece transmission and gas supply control systems are designed and manufactured, which are applied to the heating of RAL and WISCO thin strip warm rolling, realizing a breakthrough in the industrialized prototype machine.

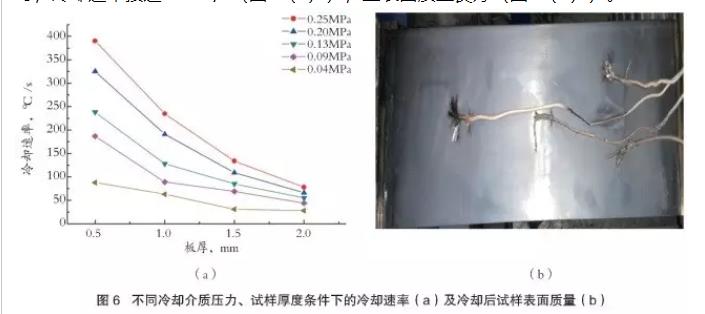

2) Carry out experimental research on non-oxidation rapid cooling technology, design the cooling medium circulation supply system and atomizing spray device, verify the feasibility and safety of the non-oxidation cooling technology, and study the effect of the pressure and flow of the cooling medium on the cooling rate of the sample Influence and limit cooling rate of different thickness specimens. The results show that as the cooling medium injection pressure increases, the cooling rate of the sample increases. For a 1mm sample, when the cooling medium injection pressure is 0.25MPa, the cooling rate is close to 240℃/s (Figure 6(a)), and the surface The quality is good (Figure 6(b)).

3) Based on the above technology, the feasibility study report and plan design of a 1500MPa ultra-high-strength steel production line have been completed. The production line is characterized by high product strength, fast heating and cooling rates, short production line length, and wideband and multi-stream narrowband. Co-production.

4) For the coating process and equipment technology, Northeastern University and Anshan Iron and Steel Group cooperated to make breakthrough progress in the core technology of hot-dip galvanized product coating quality control, successfully developed a coating thickness control system, and realized industrial application. The actual average thickness deviation of the coating is less than 3.2g/m2, which is 1.13% higher than the international advanced level; the coating uniformity 2σ is 1.25g/m2, which is 10.7% higher than the international advanced level, and an annual economic benefit of more than 60 million yuan is created. In 2015, the "Hot-dip galvanized steel strip coating quality control core technology research and development and industrial application" project completed by Anshan Iron and Steel and Northeastern University won the second prize of National Metallurgical Science and Technology. In 2016, breakthroughs were made in the industrialization of spangle spray control technology and galvanizing defect control technology. In view of the problems existing in the existing production line, it signed an application development contract with Hegang Handan Iron and Steel Co., Ltd. to solve the problem of zinc flow pattern, edge twill, and zinc. Galvanizing defects such as uneven flower size can reduce the variety of transition materials and increase the yield rate.

2.3 Thin strip continuous casting + warm rolling new technology to prepare high-precision thin strip product development platform construction

Thin strip continuous casting + warm rolling is a new full-process green manufacturing technology, which is mainly used for continuous casting, warm rolling and subsequent cold rolling deep processing of high silicon steel, high strength steel and special alloy materials, and can be used for a variety of difficult-to-deform metals Special rolling of thin strips. This direction cooperates with the short process direction, independently designed and developed the first set of thin strip continuous casting + warm rolling pilot line at home and abroad (Figure 7). The use of direct combustion flame rapid temperature increase, furnace coil insulation and online anti-oxidation technology has formed an innovative technology route for rapid solidification to improve material performance and temperature processing of difficult-to-deform metal materials: 1) Developed casting strip, hot flattening, and warm coil rolling Nitrogen micro-injection technology in the whole process and other multi-process sections effectively solves the oxidation problem in the process of thin strip casting and rolling, warm rolling to finished product; 2) The self-developed direct-fired rapid heating and furnace coiling system has been successfully applied to the thin strip In the casting and rolling line, through the application of the coupling control technology of the heat preservation of the coil box and the rapid temperature increase of the direct combustion flame, the problem of the constant temperature control of the deformation zone of the roll and the rolling piece in the warm rolling process is solved, and the 3-4mm high silicon steel thin cast strip is realized. The material is controlled by the rapid temperature-decreasing temperature rolling process, and the 0.27mm continuous high magnetic thin strip material is successfully prepared. 3) Developed the direct-fired rapid heating flame nozzle online automatic width adjustment technology device, and optimized the distribution of the nozzle combination, which solved the technical problem of direct-fired rapid heating for different incoming material widths and uniform strip surface temperature. At present, the above-mentioned advanced technology has been successfully applied in the RAL laboratory and the thin strip casting and rolling demonstration line of the National Silicon Steel Engineering Technology Center of Wuhan Iron and Steel, and has produced high silicon thin strip magnetic materials.

A breakthrough has been made in the engineering application of thin strip casting and rolling + Steckel warm rolling to produce high magnetic induction silicon steel technology. Combined with the national "863" energy-saving motor high silicon steel development project, Northeastern University and Wuhan Iron and Steel Group Corporation signed a cooperation project to use " The 2011 plan "Northeastern University Steel Generic Technology Collaborative Innovation Center's cutting-edge technology advantages in the field of thin strip casting and rolling + warm rolling, and the first set of "500mm thin strip casting and rolling industrialization demonstration lines at home and abroad" will be built in the pilot plant of WISCO National Silicon Steel Engineering Center. "Developed a prototype machine with completely independent intellectual property rights for the production of hard-to-deform thin strip materials such as 6.5% Si by continuous casting of thin strip + hot coil rolling. At the same time, it was implemented in the pilot plant of WISCO. At present, the project has completed the heat load test run of the entire line of process equipment. On April 16, 2017, the expert team of the High Technology Center of the Ministry of Science and Technology conducted the acceptance of the "Energy-saving Motor High Silicon Steel Development" project at Wuhan Iron and Evaluation opinions: 1) The production process technology of 6.5% Si steel with vacuum smelting, twin-roll casting, multi-pass reversible hot rolling, warm rolling and full-process atmosphere protection was proposed, and the 6.5% Si steel near-net shape was developed. The key equipment for manufacturing; 2) The warm rolling preparation of 6.5% Si thin steel strip was realized, and the 6.5% Si steel cold-rolled thin strip was successfully rolled; The hot/warm/cold three-purpose rolling mill with rolling function (Figure 8), through key technologies such as line atmosphere protection, hot-coil box-type coiling insulation, and direct-fired rapid temperature increase, has achieved 6.5% Si steel thin strip and coil short Process advanced technology preparation. Currently. The RAL laboratory's thin strip casting and rolling short-flow production process technology has obtained a number of industrial applications. It has signed an industrial production line for thin strip casting and rolling to prepare high value-added thin strip products with Hebei Jingye and Jiangsu Yancheng and other related companies and applied them.

relies on the RAL laboratory thin strip casting + warm rolling experiment platform. Based on the production line process equipment flow, establish the latest wireless communication technology such as field wireless communication bus network and Wi-Fi network, develop sensor wireless information communication module system, design the wireless network topology in the industrial environment, in the thin strip casting and rolling experiment line , Successfully developed an integrated communication system for rapid transmission of field bus and sensor wireless information, realizing fast and reliable data transmission from sensor nodes to aggregation nodes to PLC through Zigbee protocol and TCP/IP protocol, meeting the steel production process Different process characteristics and requirements. Through the collection, processing and transmission of the information status of the equipment in the metallurgical production line, the application of the mobile terminal system is transplanted to the industrial control system, and the equipment data status is displayed on the typical mobile client with three-dimensional images to realize the experimental research of thin strip casting and rolling The platform (such as smelting, casting, warm rolling, scorching and collection, etc.) experiment and production process dynamic simulation of the whole line, and the data monitoring and real-time dynamic monitoring of each process section of the experiment process. At the same time, it greatly simplifies the interconnection and information exchange of control equipment in each process area, and intelligently integrates wired and wireless network data to solve the need for rapid and flexible intelligent perception of detection data during the production process, which is the product quality under complex process conditions. Provide technical support for comprehensive management and control of performance and performance.

Developed and designed an industrialized wireless network architecture, wirelessly connected to various process control areas and production line instruments, simplifies the information exchange between equipment in the process area, and is suitable for flexible adjustment and quality control of the production process; the development is aimed at the storage and processing of big data during the production process. A high-speed data acquisition system based on a fieldbus network supports high-speed data acquisition of wireless data, and analyzes the needs of a distributed information processing platform in view of the defects of centralized storage and computing. At present, a standard analog signal wireless sensor template has been developed and high-speed signal transmission has been realized.

Conclusion

The research and development of high-precision rolling and heat treatment process and equipment technology for thin strip steel provides important technical support for the production of high-end cold-rolled plate and strip steel products. In particular, the green thin strip casting and rolling high magnetic induction electrical steel technology has completely changed the traditional electrical steel The production process and composition design of the company can produce high-quality electrical steel with different silicon content and different thickness at lower cost, simpler process, higher quality, and less investment, which is important for the sustainable development of my country's national economy and national security. has great significance.

Hot News

黄石山力科技股份有限公司

Sunny Technologies Incorporation Limted

Contact us

Add:No. 2, Guangzhou road, tuanshancheng Development Zone, Huangshi City, No. 101, Gaoxin 6th Road, Donghu New Technology Development Zone, Wuhan

Mail:spt@sunnychina.com.cn

Tel:156 7177 7755 / 027-59715061

Fax:027-59715060