NEWS CENTER

Inhibitors in oriented silicon steel

- Time of issue:2020-10-12 02:20

(Summary description)Oriented silicon steel refers to a Si-Fe soft magnetic material with a Si mass fraction of 2.9% to 3.5%. It is mainly used to make various distribution transformers and large generator stators. Its performance seriously affects the efficiency of national power transmission. Compared with other types of soft magnetic materials, oriented silicon steel has more stable performance and can be used in certain specific environments such as high temperature and impact; its price is also relatively cheap, the process is more mature, and it is suitable for mass production in industry.

Inhibitors in oriented silicon steel

(Summary description)Oriented silicon steel refers to a Si-Fe soft magnetic material with a Si mass fraction of 2.9% to 3.5%. It is mainly used to make various distribution transformers and large generator stators. Its performance seriously affects the efficiency of national power transmission. Compared with other types of soft magnetic materials, oriented silicon steel has more stable performance and can be used in certain specific environments such as high temperature and impact; its price is also relatively cheap, the process is more mature, and it is suitable for mass production in industry.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-10-12 02:20

- Views:

1 Introduction

Oriented silicon steel refers to a Si-Fe soft magnetic material with a Si mass fraction of 2.9% to 3.5%. It is mainly used to make various distribution transformers and large generator stators. Its performance seriously affects the efficiency of national power transmission. Compared with other types of soft magnetic materials, oriented silicon steel has more stable performance and can be used in certain specific environments such as high temperature and impact; its price is also relatively cheap, the process is more mature, and it is suitable for mass production in industry. The process and equipment used in the production process of oriented silicon steel are very complicated, the requirements for chemical composition are extremely strict, the specified composition range is very narrow, the requirement for extremely low impurity content and many factors affect performance, its manufacturing capacity and quality measure the steel of a country Metallurgical level.

In terms of magnetic properties, the magnetic properties of the oriented silicon steel along the rolling direction are closely related to the strength of the secondary recrystallization {110}<110> texture (Goss texture); the enhancement of the Goss oriented grain component in the finished oriented silicon steel sheet can be The magnetic induction performance is greatly improved. In the production process of oriented silicon steel, in order to control the recrystallization process and obtain a single sharp Goss texture, grain inhibitors (meta-stable second-phase precipitation particles) are indispensable. From the current industrialized and stable production of oriented silicon steel products, reasonable control of inhibitor precipitation is the key to ensuring the texture and performance of oriented silicon steel [1]. Therefore, how to use and control the precipitation of inhibitors and play their role has always been a hot issue in the research of oriented silicon steel.

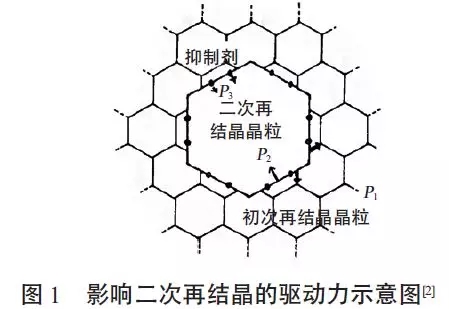

2. The mechanism by which inhibitors promote the formation of Goss texture

Secondary recrystallization is a kind of abnormal growth of crystal grains, that is, only a small part of the crystal grains in the primary recrystallization matrix will suddenly and rapidly grow into larger grains. The calculation of the grain growth rate during the secondary recrystallization process is shown in Equations 1 and 2 [2]: dR/dt=MP (1) P=AE{(1/RC)-(K/R)-(KZ/A) } (2) where M is the grain boundary mobility; P is the total driving force for grain growth; A is the geometric coefficient; E is the average grain boundary energy of the first recrystallized grains; Rc is the critical size of the first recrystallized grains; K is the ratio of the grain boundary energy of the secondary recrystallized grains to the primary recrystallized grains; R is the size of the secondary recrystallized grains; Z is the Zener factor, that is, the driving force of the secondary recrystallization driving force stored by the primary matrix ( P1), the resistance of the secondary recrystallization grain growth (P2) and the pinning force of the inhibitor (P3) are composed of three parts (see Figure 1).

According to Zener's formula [3], the restraining force Z of the second phase particles on grain boundary migration can be expressed as follows:

Z= 3σf4r (3) where σ is the grain boundary energy; f is the volume fraction of the second phase particles; r is the average radius of the second phase particles. The larger the number of precipitates and the smaller the size, the stronger the pinning ability for the growth of the primary recrystallized grains, and the higher the driving force for the primary matrix to store the secondary recrystallized.

Regarding the mechanism by which inhibitors promote the preferential growth of Goss-oriented grains during the high-temperature annealing stage, there are mainly two theories at this stage: the coincident position lattice model (CSL) and the high-energy grain boundary model (HE). The coincidence position lattice model believes that CSL grain boundaries have lower energy than other ordinary large-angle grain boundaries. In the heating stage of the secondary recrystallization annealing, before the inhibitor particles are coarsened or decomposed, the Goss grains with high overlap lattice grain boundaries have lower grain boundary energy, and the pinning force of the particles is weaker than that of ordinary grains. When the particles are coarsened or decomposed, this part of the grain boundaries can be preferentially freed from the pinning of the particles to undergo secondary recrystallization, which leads to the abnormal growth of Goss grains. The high-energy grain boundary model believes that the growth of Goss grains is based on the physical properties of high-energy grain boundaries with an orientation difference of 20°~45°. High-energy grain boundaries have more point defects than other grain boundaries, which leads to higher grain boundary migration rate and grain boundary diffusivity, and the coarsening speed of particles on high-energy grain boundaries is faster than other grain boundaries. Therefore, during the secondary recrystallization process, the Goss grains can be quickly separated from the particle pinning and migrate.

In summary, the effect of inhibitors in oriented silicon steel is mainly to inhibit the growth of normal grains during the initial recrystallization annealing stage, which is the driving force for secondary recrystallization storage, and to promote the abnormal growth of Goss oriented grains during the secondary recrystallization annealing. Big. Although the dispersed fine precipitates can pin the grain boundaries and inhibit the growth of primary grains, whether they can be used as effective inhibitors depends on whether they can aggregate and dissolve as the temperature rises during the high-temperature annealing process. , And finally removed by H2 at a high temperature of 1 200 ℃, so as not to inhibit the growth of primary grains while also hindering the growth of secondary recrystallized grains. Inhibitors can be divided into two categories, one is compounds such as sulfides and nitrides, and the other is elemental elements that tend to segregate at grain boundaries. This article combines my own research and published literature at home and abroad to briefly introduce the types of commonly used inhibitors and their effects.

3. Compound inhibitors commonly used in oriented silicon steel

3.1MnS

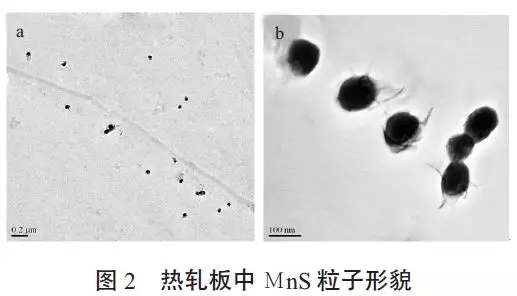

MnS is the first compound used as an inhibitor in the history of oriented silicon steel manufacturing. Traditional oriented silicon steel mainly uses MnS as an inhibitor. MnS generally preferentially nucleates and precipitates at crystal defects such as dislocations and grain boundaries during the hot rolling stage, which is affected by the heating and hot rolling process of the cast slab [4]. In order to ensure that MnS can be finely dispersed and precipitated during the hot rolling process, the cast slab needs to be heated to a temperature of 1350°C or higher to ensure that the coarse MnS particles in the cast slab can be fully dissolved, which will bring a series of problems to the production. For example, there are many oxide slags, large burning loss, low yield, and many product surface defects. During the hot rolling stage, MnS begins to precipitate at about 1250°C, and the fastest at about 1150°C, and at about

The precipitation basically stopped at 950°C. During the precipitation of MnS, the number and average size of particles are continuously increasing, and the rate of increase depends on the content of Mn and S.

Generally, it is stipulated that the mass fraction of Mn in oriented silicon steel is 0.05% to 0.12%, and the mass fraction of sulfur is 0.015% to 0.030%. The coarse MnS in the cast slab is generally precipitated as spherical nano-scale precipitates after the slab is reheated and hot rolled (see Figure 2), the size is less than 100nm, and the distribution density is about 1012-1014 per cubic centimeter. The effect of inhibiting the first grain growth. With MnS as the suppressed oriented silicon steel, the secondary recrystallization temperature is usually between 870°C and 925°C. During the secondary recrystallization annealing process, when the temperature continues to rise, the MnS particles will gradually coarsen or dissolve, and the pinning effect on the grain boundary will become weaker and weaker until it disappears. After the secondary recrystallization is promoted to be fully completed, in a temperature >1150°C and a pure H2 atmosphere, H2S is generated by the reaction of S and H2, which is decomposed and volatilized and removed, completing the purification of the oriented silicon steel product.

3.2AlN

In order to reduce the reheating temperature, AlN obtained in the subsequent process section of hot rolling is mainly used to replace MnS to produce medium and low temperature oriented silicon steel. At this stage, two methods can be used to precipitate AlN particles with high suppression strength in the process stage before the final high-temperature annealing: one is by performing (1120~1150)℃×(2~3)min→(920~ 950) ℃ × (2 ~ 3) min two-stage normalizing annealing before cold rolling to obtain a large amount of nano-scale AlN, which belongs to the primary inhibitor; the other is decarburization annealing by performing (750~900) on the sample ) ℃×(5~60)s continuous nitriding treatment to obtain a sufficient amount of nano-scale AlN, which is a secondary inhibitor. During normalizing annealing and nitriding heat treatment, the number and average size of particles also increase continuously, and the rate of increase depends on the acid-soluble aluminum (Als) content and the N content in the steel.

The mass fraction of Als in oriented silicon steel is generally controlled at 0.015% to 0.035%, and the mass fraction of N is generally controlled at 0.006% to 0.013%. AlN is initially precipitated during the hot rolling process. Due to the large volume of the slab, the cooling is slower in the cooling stage, resulting in that the AlN obtained in the hot rolling stage will be slightly larger than the effective suppression size. Therefore, hot rolling usually adopts rapid rolling and rapid cooling processes. It is desirable to minimize the precipitation of AlN. After the hot-rolled sheet is normalized, AlN precipitates out as rectangular or irregularly shaped nano-scale precipitates (see Figure 3), with a size of about 20-100nm, which has a strong inhibitory effect. With AlN as the main inhibitor, the magnetic properties of the products obtained when high temperature normalization and cold rolling under a large reduction are used to produce oriented silicon steel are unstable. By using AlN and MnS together, a sharper Gaussian can be obtained after high temperature annealing. Texture. In the high temperature annealing process in pure H2 atmosphere, when the temperature rises to 1100℃~1200℃, AlN will be absorbed by the glass film on the surface of the sheet and decompose rapidly. The decomposed N and H2 will react to form NH3 and volatilize. Purification of oriented silicon steel products.

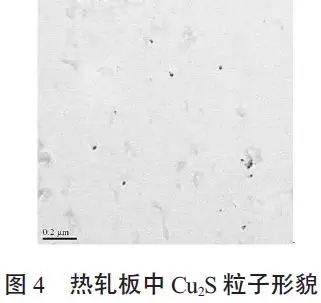

3.3 copper sulfide

In order to reduce the reheating temperature of the slab and improve the magnetic properties, many manufacturers add a small amount of Cu during the production of oriented silicon steel to produce Hi-B steel with medium temperature heating (1250℃~1300℃). The main types of Cu inhibitors in Cu-oriented silicon steel include Cu2S, (Cu, Mn) 1.8S and Cu1.8S. The solid solution temperature of Cu2S is about 100°C lower than that of MnS, and its particle coarsening speed is much smaller than that of MnS. The Cu2S particles have a significant pinning effect on grain boundary migration when the size of Cu2S particles is 30-100nm. The size of Cu2S particles precipitated in oriented silicon steel is mainly within 10-50nm. The morphology and distribution of typical Cu2S particles are shown in Figure 4. Cu2S particles can be precipitated in the stages of continuous casting, hot rolling, intermediate annealing and initial recrystallization annealing, and a large amount of precipitation begins at the hot rolling stage; in the process before high temperature annealing, the number of Cu2S particles is continuously increasing, and the size Shows a growing trend [5].

(Cu, Mn) 1.8S and Cu1.8S are usually used as auxiliary inhibitors, which are mainly precipitated in the hot rolling stage. Cu1.8S is mainly generated when the mass fraction of Cu in the steel is 0.15% to 0.20%, and its solid solution temperature is 1200°C to 1250°C, and the precipitation peak value is about 1000°C. A large amount of fine (Cu, Mn) 1.8S will be precipitated during the γ→α phase transition during finishing rolling at 1150℃. The size of (Cu, Mn) 1.8S is smaller than that of (Cu, Mn) S, and the size is about 30-50nm. With the increase of Cu content, the ratio of Cu to Mn in the precipitates keeps increasing, and the size of the precipitates Will continue to decrease [6]. Copper-sulfur compounds are used as inhibitors to produce oriented silicon steel, and the inhibitor's inhibitory ability in steel is between that of oriented silicon steel with MnS and AlN as the main inhibitor [5].

4. Single element solute inhibitor commonly used in oriented silicon steel

4.1Sn

Sn is one of the more commonly used auxiliary inhibitors for high magnetic induction oriented silicon steel. Adding an appropriate amount of Sn can significantly improve the magnetic properties of the steel, and its mass fraction in the steel is generally controlled at 0.05% to 0.10%. Sn is a surface active element, which is initially precipitated along the grain boundary during the process of crimping and normalization, which helps to uniformly distribute the γ phase and α phase during the normalization process, so that larger ferrite crystals can be obtained after normalization. Grains further promote the formation of more deformed bands during the cold rolling process, increase the number of secondary recrystallized nuclei, thereby reducing iron loss.

Sn can segregate at the interface between MnS, AlN and the matrix, thereby inhibiting the coarsening of these particles and making them more finely dispersed, which can enhance the inhibitory strength of the steel and improve the orientation and magnetic properties of the steel. The study of Fan Lifeng et al. [7] showed that compared with steel without Sn, after adding 0.19% of Sn by mass, the precipitates in the steel became finer, and the precipitation inhibition ability was significantly increased. At the same time, they used a scanning Auger microprobe to study the segregation of Sn along the grain boundary during the high-temperature annealing stage, and found that the content of Sn segregated at the grain boundary was about 17.41 times the average Sn content in the steel, which proved that the final secondary repetition During the crystallization annealing process, Sn will segregate on the grain boundaries and hinder the normal growth of the primary grains, acting as an auxiliary inhibitor. This segregation of Sn mainly occurs on the ordinary high-angle grain boundaries, so it will increase the speed of movement between the overlapping lattice grain boundaries dominated by Σ9 grain boundaries around the Goss secondary crystal nucleus and the ordinary high-angle grain boundaries. Poor, promote the growth of Goss grains.

4.2Sb

Sb is a grain boundary segregation type solute element. Adding a small amount of Sb in conjunction with compound inhibitors in the production process of oriented silicon steel can achieve a better inhibitory effect and contribute to the formation of Goss texture. Fan Lifeng et al. [8] conducted research on hot-rolled Sb-containing oriented silicon steel sheets and found that with the increase of Sb content, the Goss texture content in the hot-rolled sheet will increase, reaching the maximum when the Sb mass fraction is 0.04%.

Sb element segregates on the grain boundary during the decarburization annealing stage, inhibits decarburization and primary recrystallization, prevents the nucleation and growth of {111} plane grains, and significantly increases the {110} composition and the number of secondary crystal nuclei . The addition of Sb will enhance the suppression ability of the high temperature annealing stage, increase the starting temperature of secondary recrystallization, thereby improving the accuracy of the Goss orientation, promoting the formation of sharp Goss texture, and ultimately improving the magnetic properties of oriented silicon steel [9,10 ]. Kawasaki Company [11] conducted research by adding an appropriate amount of Sb to oriented silicon steel with MnSe and AlN as the main inhibitors, and found that the segregation of Sb at the grain boundary can reduce the primary grains while also significantly inhibiting the central grain of the steel plate. The growth of grains and their segregation on the surface of the steel plate can also prevent the decomposition of surface MnSe and nitrogen increase during the high-temperature annealing process.

4.3Mo

Mo is a ferrite-forming element. It can inhibit the phase transformation process of ferrite→austenite+ferrite→ferrite in the hot rolling stage, and significantly inhibit the dynamic recrystallization of the surface layer, thereby promoting a greater number of formations in the hot rolling stage. More high-strength Goss textures can reduce the iron loss of oriented silicon steel products and improve the magnetic properties. Inokuti et al. [12] added 0.013% Mo to the grain-oriented silicon steel with MnSe as the main inhibitor, and studied the influence of Mo on the structure of the grain-oriented silicon steel intermediate annealing plate, and found that the grain size of the intermediate annealing plate decreased from 21μm after adding Mo As small as 19μm, the volume fraction of Goss texture increased from 8%-22% to 20.7%-40.2%. It is also analyzed that Mo is mainly used to promote the formation of more grains in {111}<112> orientation grains in the primary cold rolling stage. The shear deformation band promotes the formation of Goss texture in the intermediate annealed sheet. The addition of Mo will significantly increase the inhibition ability of MnS and AlN, increase the secondary recrystallization temperature by 15°C to 20°C, and enhance the sharpness of the Goss texture in the final high-temperature annealing stage. The addition of Mo can also effectively reduce the heating temperature of the cast slab. When the Mo-containing steel is heated at 1310°C, the hot-rolled texture obtained is similar to that of the Mo-free steel when the cast slab is heated at 1380°C, resulting in decarburization. The surface texture of the board can still maintain a sufficiently strong (111) orientation component. When the cast slab is heated at high temperature, Mo will also be enriched on the surface and prevent oxidation of the surface and grain boundaries, or form fine Mo2Si3 near the surface to prevent the formation of FeS and prevent grain boundary cracks [13].

5 Inhibitor application status in the production of oriented silicon steel

According to the difference in magnetic properties, oriented silicon steel can be divided into ordinary oriented silicon steel (CGO) and high magnetic induction oriented silicon steel (Hi-B). The magnetic properties of CGO steel are between 1.80~1.85T, and the magnetic properties of Hi-B steel are greater than 1.89 T. At present, there are only more than ten enterprises in the world that can industrially produce oriented silicon steel products. In order to reduce the reheating temperature of the slab as much as possible and improve the magnetic properties of the products, the types of inhibitors used by the enterprises in the production have been changed from the original single MnS to MnS. , AlN, Cu2S and various single-element solute inhibitors.

In the production of CGO steel, enterprises at this stage usually use MnS or Cu2S as the mainstay, supplemented by AlN, and the reheating temperature is between 1250℃ and 1300℃. , Germany Thyssen, etc. The production of Hi-B steel usually uses AlN as the main inhibitor, MnS, MnSe, and Cu2S as auxiliary inhibitors, and adds a small amount of Sn, Sb, etc., such as Germany Thyssen, Japan JFE, etc., and the heating temperature is 1300℃ the following. Nippon Steel, China Baowu Group, South Korea's Pohang and other companies did not change the types of Hi-B steel inhibitors while using the cold-rolled annealing post-nitriding process to produce products with higher inhibitor suppression strength and better magnetic properties. , And the reheating temperature drops below 1250°C.

5 Conclusion

For the production of oriented silicon steel, inhibitors are indispensable. The main function of the inhibitor is to inhibit the growth of normal grains during the initial recrystallization annealing stage as the driving force for secondary recrystallization storage, and to promote the abnormal growth of Goss-oriented grains during the secondary recrystallization annealing. Some inhibitors can also play a role. It promotes the formation of Goss texture in the hot rolling stage and secondary recrystallization nuclei in the decarburization annealing stage. There are many kinds of inhibitors. Compound inhibitors are usually used as main inhibitors, and single-element solute inhibitors are usually used as auxiliary inhibitors. The combination of the two can achieve a better inhibitory effect. Using AlN as the main inhibitor, Cu2S as the auxiliary inhibitor, adding an appropriate amount of Sn or Sb and combining with the nitriding process is the development direction for the production of high-quality oriented silicon steel.

Hot News

黄石山力科技股份有限公司

Sunny Technologies Incorporation Limted

Contact us

Add:No. 2, Guangzhou road, tuanshancheng Development Zone, Huangshi City, No. 101, Gaoxin 6th Road, Donghu New Technology Development Zone, Wuhan

Mail:spt@sunnychina.com.cn

Tel:156 7177 7755 / 027-59715061

Fax:027-59715060